|

| |

|

|

|

|

|

----------------------------------------------------------------------------

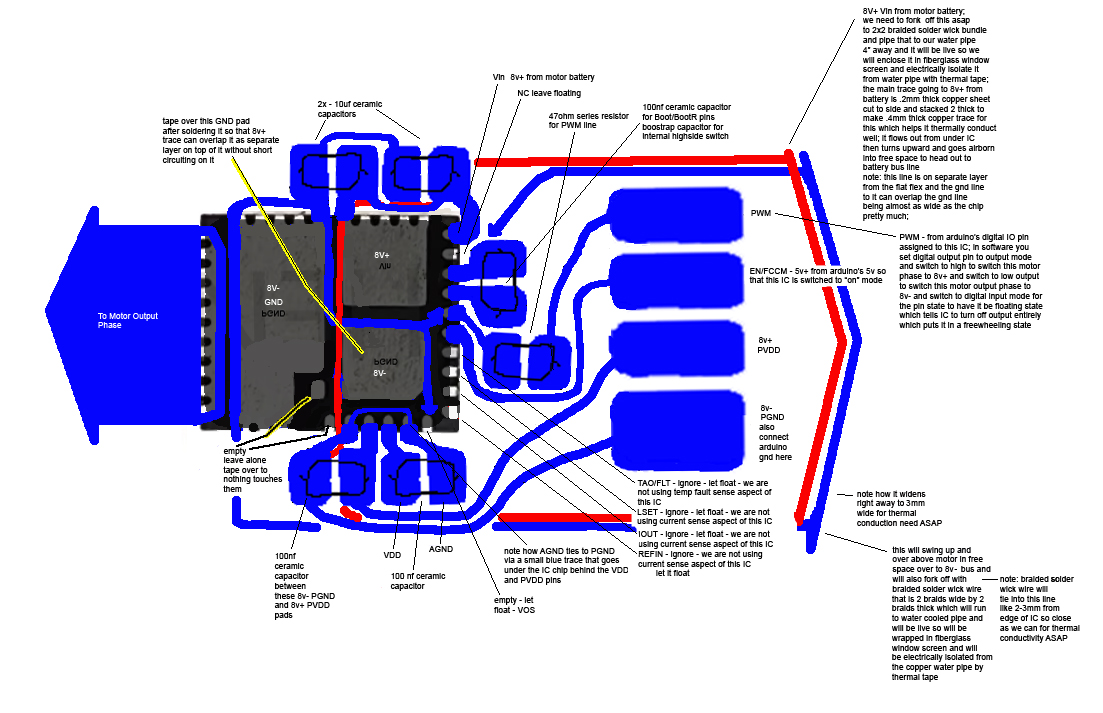

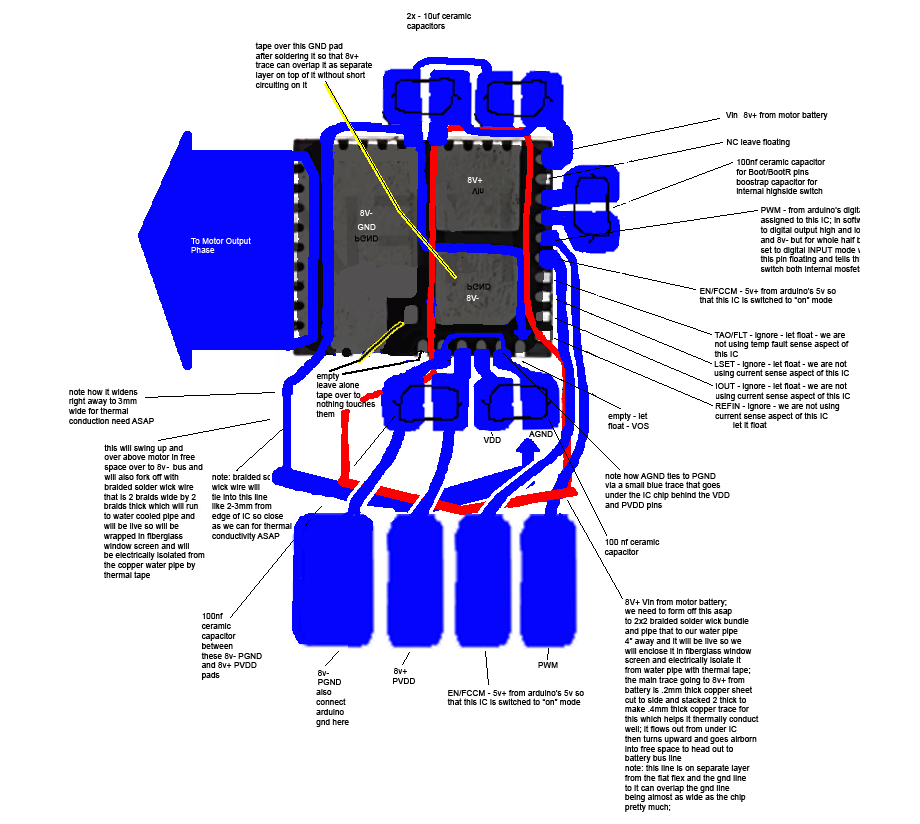

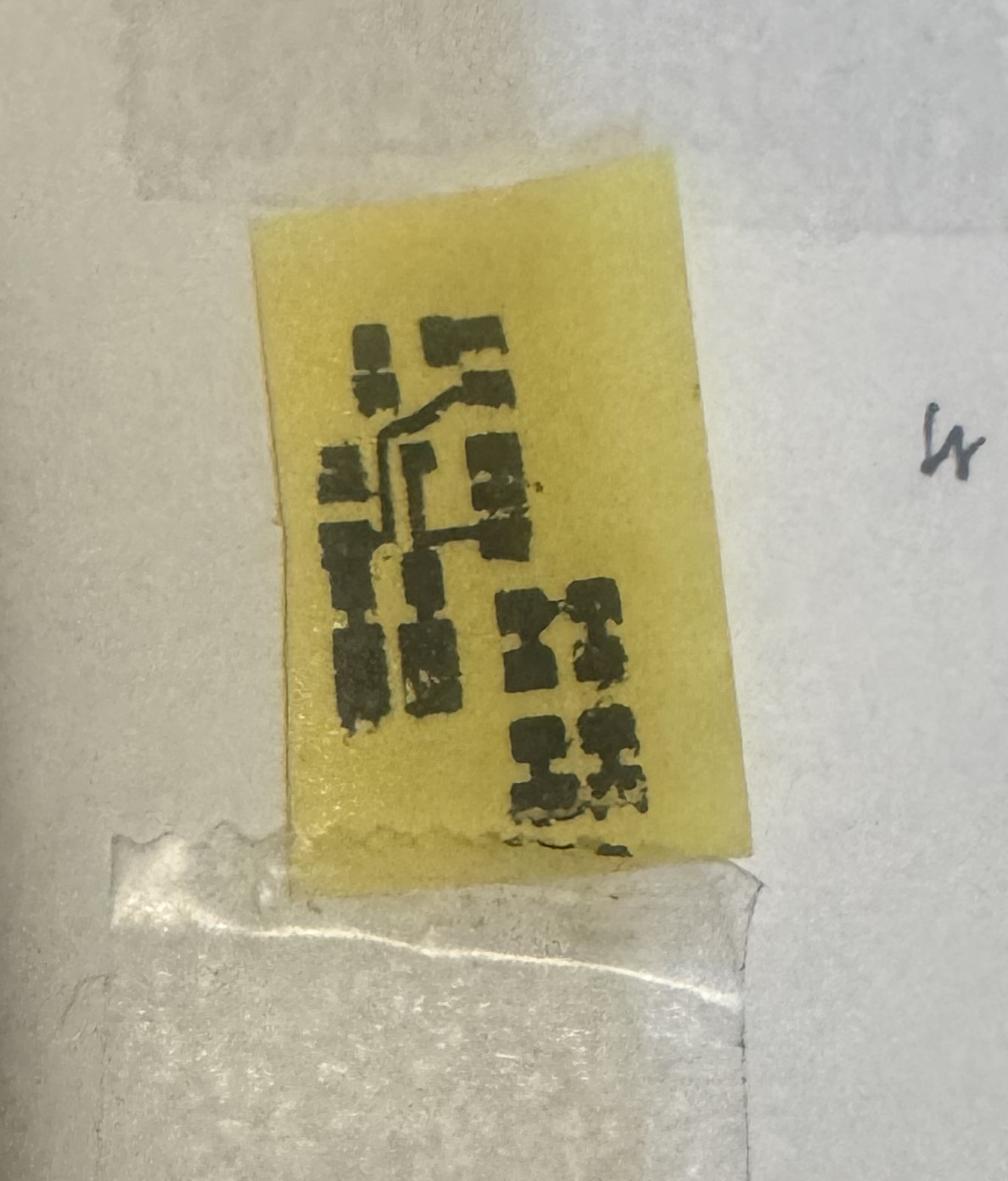

Blog Post #112, submitted 1/20/26 Ok so I was thinking now that each half bridge is just a tiny IC rather than a pair of hefty power mosfets, the space taken up overall by my entire bldc motor controller is going to be about 3cm x 1cm x 2mm which is insanely small for 30a continuous at 8v motor controller! This realization caused me to reconsider whether I even need to treat this as a single motor controller cluster that has to be sat like a horse saddle onto the side of my bldc motor - my original intention for my discrete components original design for my original bldc motor controller. What I realized instead is that things are now so small that I can simply build a half bridge for each phase as a inline element nested inside the cable run leading to each phase wire of the bldc motor. So instead of having a dedicated spot for each motor controller, I'm going to have just a slight bulge in the phase wire leading out from the bldc motor and that bulge will contain the half bridge that handles that phase wire. All nested inline. This is the easiest way to implement and most streamlined I think. It also means the whole motor controller will just be "floating" in midair, not actually mounted to any motor or anything at all. Just part of the wire harness nested right in there. This is a radical approach IMO. Only made reasonable by the fact we miniaturized the design by such an insane degree. So the previous version of the schematic was intended to be mounted to the side of the motor like a horse saddle and had an l shape so inputs would come up from bottom and outputs out to left side toward motor phase wires. These L shaped half bridge setups would be stacked next to eachother side by side. In the new variation everything is inline, inputs coming from right and outputs exit out left side to motor. Here's the updated inline variation of the schematic (no longer L shaped flow like before).

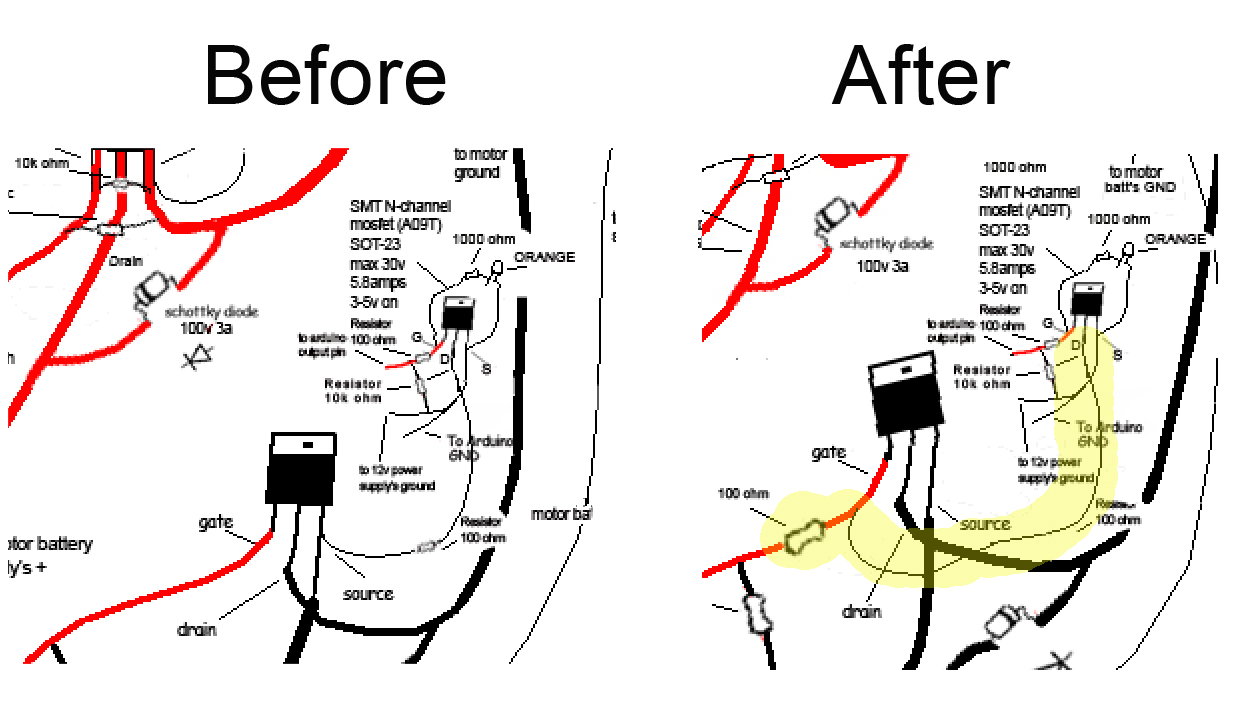

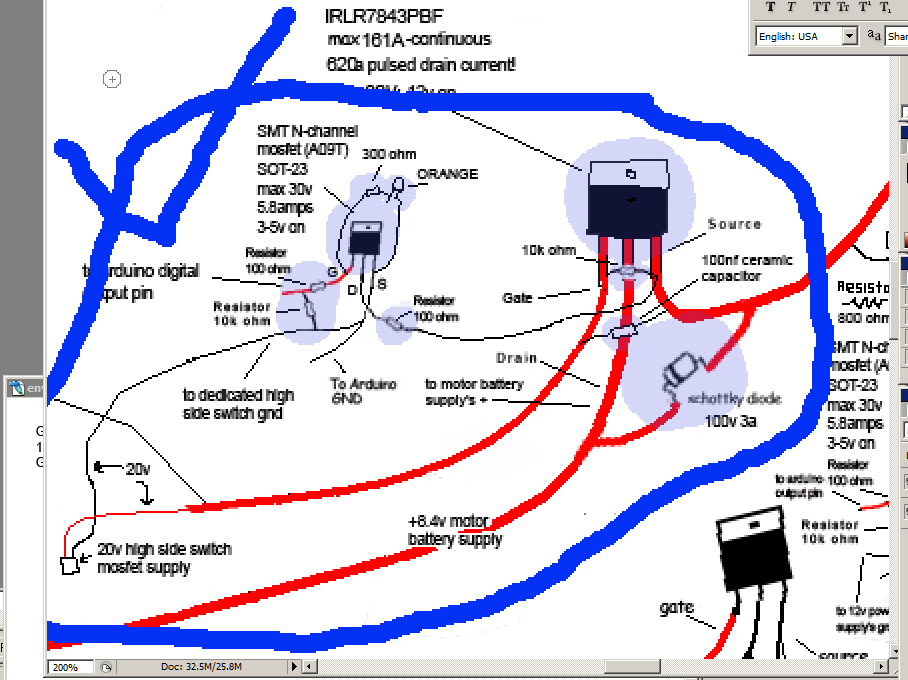

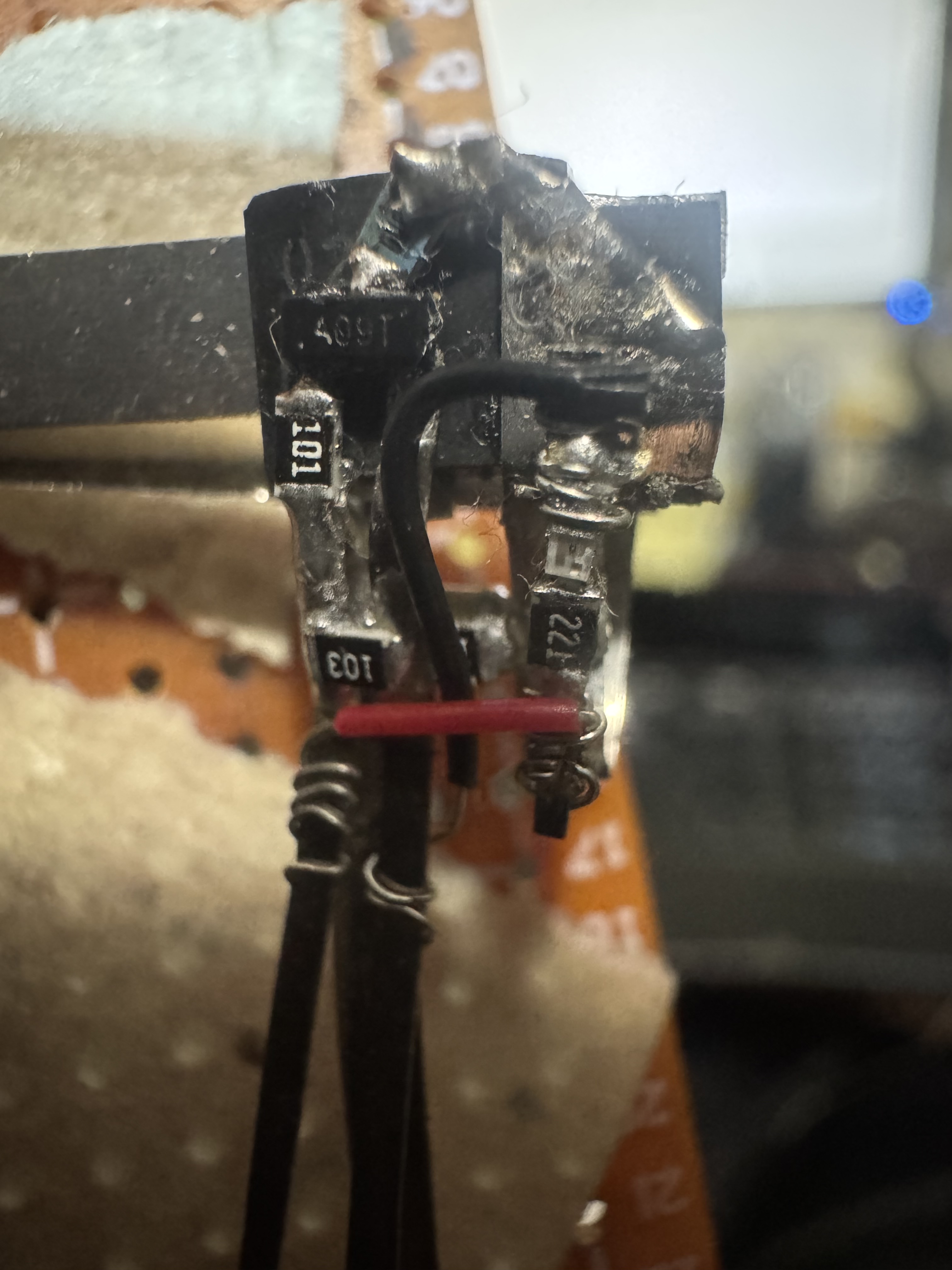

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #111, submitted 1/20/26 OK, so when I was thinking of using both my discrete components motor controller design parts I already made and then also separately implementing the integrated half bridge IC design going forward, it hit me that the 8v- and arduino gnd tie together on the half bridge IC by necessity but this ruined their intended isolation I needed for my discrete components motor controller design particularly for the lowside switching portion of that schematic. On the lowside switching portion, the little mosfet has 12v- and arduino gnd tied to its source pin. If on the integrated half bridge I also have to tie arduino gnd and 8v-, then that means 12v- and 8v- and arduino gnd are all tied together always. That completely ruined the necessary isolation between arduino gnd/12v- and 8v- that I had intended to be in place for my lowside switch setup. So that was bug #1 freshly introduced that I would then need to solve for in my discrete components motor controller design. When studying this out on the discrete components motor controller design, another error hit me: when any lowside switch turned on in the design, the 12v- dedicated power supply gnd and the 8v- motor supply gnd become connected as long as that lowside switch is on. Since every lowside switch had always access to 8v gnd on its source pin, then even one moment of 12v gnd and 8v gnd attachment anywhere on the robot would cause every lowside switch in the entire robot to immediately turn on at the same time. So if any turned on, then all turned on. This was a huge oversight. For some reason since I only designed and focused on one half bridge conceptually at a time, I did not consider the effects one half bridge has on its neighboring half bridges. This just never occurred to me. I guess conceptually I envisioned that every half bridge had its own personal 12v ground from its own personal 12v supply that was electrically isolated from the entire rest of the robot. But of course that's not practical even if it is technically possible. So in testing, things did work, but would have failed as soon as I tried to test more than one half bridge at a time. So I caught this bug before testing revealed it. I discussed this horrible situation with chatgpt and it taught me that in a complex system like a robot, grounds of all your different supply rail voltages cannot be relied on to be isolated from one another like I was treating it. Even if at times they were momentarily, one switch, one change and suddenly they are not and it all becomes a common system ground again. So if I can't safely assume a ground for any given voltage is safely disconnected from the grounds of other voltages, I should not rely on switching on and off access to any particular ground to any of my lowside switches. Instead, I should be shorting the gate driver of the lowside switches to ground to shut them off rather than messing with their source pin's ground connections like I was before. I am to leave the source pin's ground connection as 12v- and its gate connection as 12v+ at all times except when I want to shut it off - at which point I short the gate pin to gnd using my logic level mosfet to do so. The fix was very straightforward and minor: I just had to add a 100ohm resistor in series with the gate pin of my big power mosfet lowside switch and then reroute my little mosfet a09t drain pin to the big lowside mosfet's gate pin instead of its source pin. The connection to its gate pin must be downstream of that 100 ohm series resistor so that the path from the big mosfet's gate pin has almost zero resistance when traveling through the little mosfet's drain line and over to its source line into ground. This way when you turn on the little mosfet, the big mosfet's internal capacitor quickly empties out, flushing into the path to ground created by the little mosfet and that discharges the big mosfet, shutting it off. When you want it back on, you shut the little mosfet off, which allows the big mosfet's internal capacitor to charge up again, which turns the big mosfet back on. So the setup now acts like a normally on relay. Note: the resistor on the drain line of the little mosfet that we used to have when it fed into the source line previously is now removed. We want no resistance on there because that would impede the little mosfet's ability to discharge the big mosfet's internal capacitor in a timely manner. We want to be able to not only discharge that capacitor quickly but also direct all incoming current from the 12v+ line that makes it past the 100ohm resistor heading for that big mosfet's gate into our ground path. This rapid redirect flushes so much of that already limited current that hardly any can make it inside the gate of the big mosfet which causes the gate of the big mosfet's voltage to approach near zero volts. So it's called a "pull down" path to ground. Attached is a photo of my schematic before and after the fix.

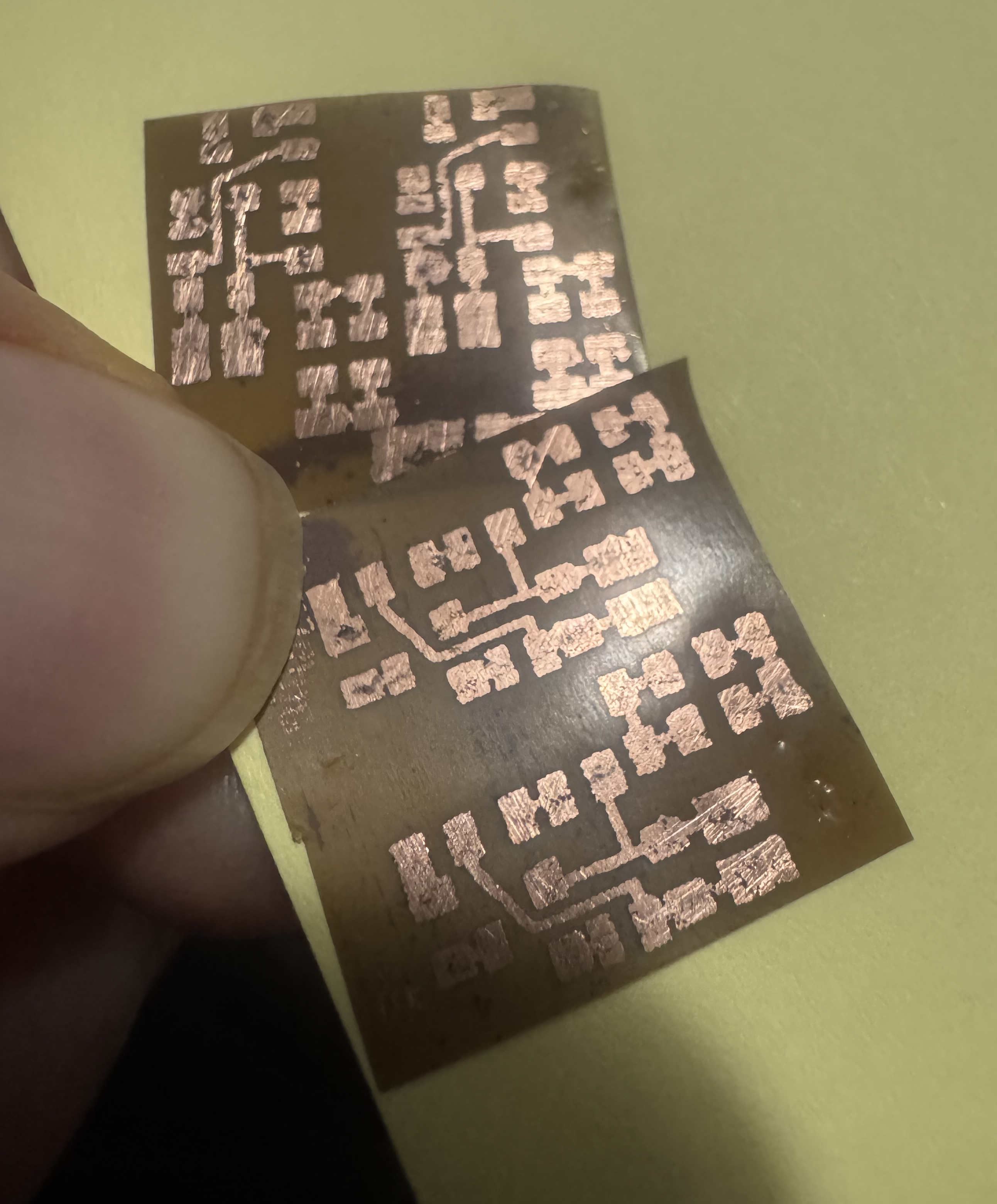

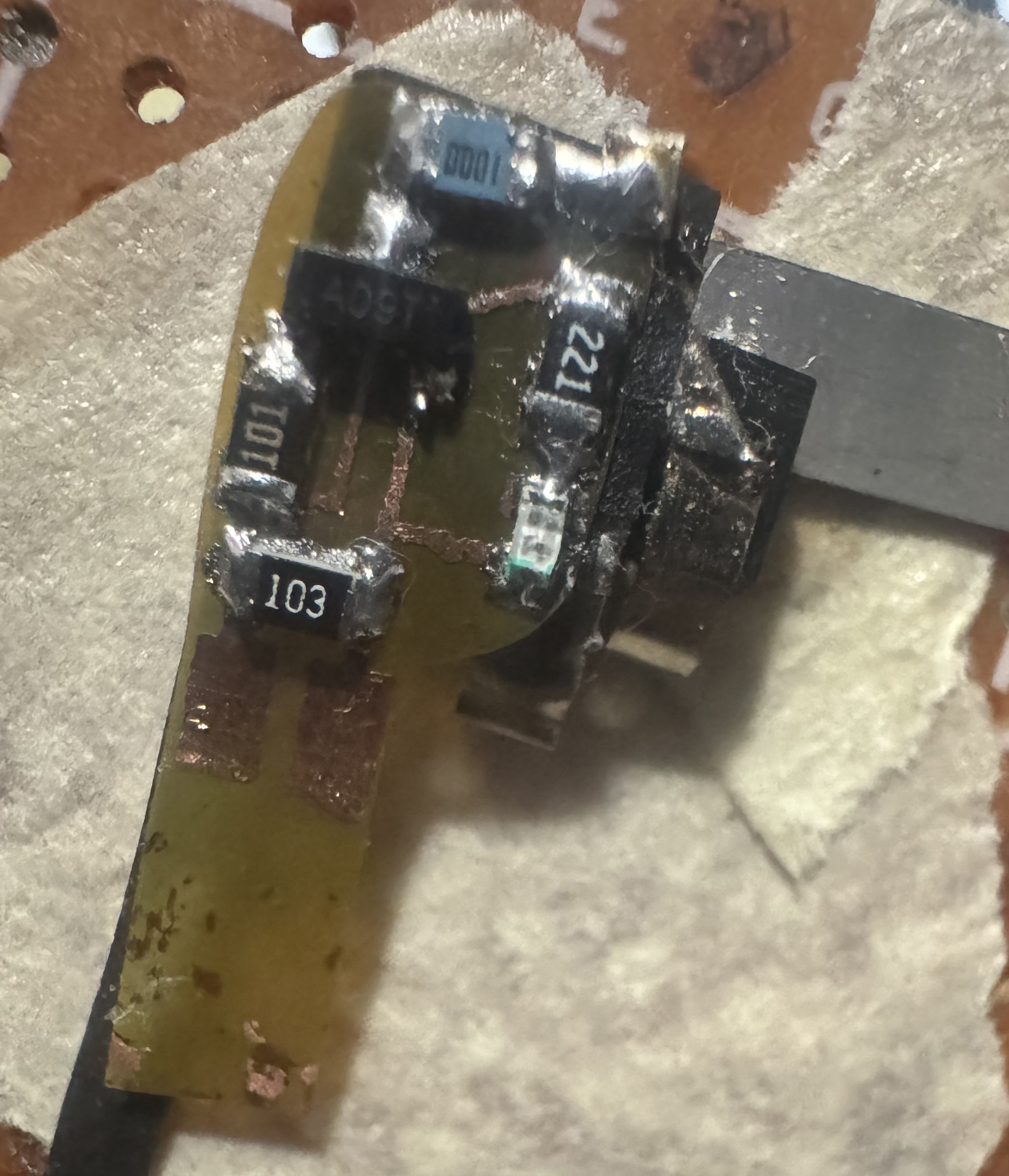

Attached is a photo of full updated schematic with the changes in place.

That all having been said, this discrete components original bldc motor controller design, now fixed, is worth keeping archived, but is now basically abandoned now that I have access to the time, money, and space saving shortcut of my integrated half bridge IC based design. It's kind of sad to abandon something I spent so much time on, but who knows, I may still use it if I ever come across a motor that I can't find a cheap half bridge integrated IC for in the future. It's a great schematic to have at the ready for that scenario. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #110, submitted 1/18/26 Well I deep dove into the CSD95481RWJ IC route. I estimate it will cut the work in half roughly for every motor controller made and cut the size taken up by about 60% compared to my previous discrete components approach. Now I will note that I did come across the BTN8982TA which is rated to 40v and can handle 30a continuous 50a peak short burst. But it's TO-263 form factor so about 4 times as big as the CSD95481RWJ. It also costs about $2 each so double the price. It's not a bad option though all things considered but just not quite as good as the CSD95481RWJ for the reasons mentioned. I note it here so I don't forget about it. It can be a great option if the CSD95481RWJ doesn't work out in the end or something. Also of note: CSD95377Q4M is a similar part to compare prices on and is rated to handle 35a continuos so is comparable and similar price - just in case this CSD95481RWJ IC ever goes out of production - this one will easily step in to fill its shoes! Anyways, for the thermal concern - which is my biggest concern, I plan to top cool the CSD95481RWJ using a .2mm plate thermal siliconed into place on top of the CSD95481RWJ and then solder a bundle of 4 braided solder wick wires to that and run that off to the water cooled copper pipe about 4" away. The top cooling only handles about 30% of the cooling according to chatgpt. The most important 70% is from the bottom cooling through its pads on its bottom. For this I plan to use double stacked .2mm thick copper plate soldered to its IC pads. So that's .4mm thick. Also it will be around 2mm wide where it attaches to the pads. It will then route out from under the chip and swing upward into free space and head over to the 8v+ and 8v- buses coming from the 8v motor battery banks in the robot's lower torso. These thick copper traces I will fork off of with braided solder wick wire right near the CSD95481RWJ IC chip for thermal conductivity reasons. This braided solder wick wire will be live so I will wrap it in fiberglass window screen so nothing can touch it - preventing short circuits. It will then be electrically isolated from where it connects to the water cooled copper pipe with thermal conductive tape. The braided solder wick wire attaching to these thick copper traces will be a bundle of 4 per trace. The various decoupling capacitors this chip calls for I will connect to its output pins using flat flex PCB DIY hand made. I'll be attaching this PCB first and attaching the thick copper traces to the underside pads second as a separate layer that goes underneath the flat flex PCB layer. The flat flex PCB layer will mostly stay around the outsides of the chip and have its center cut out and removed - the part of it that would get in the way of the underside main pads under the chip. So the flat flex PCB will just hug the outsides of the IC mainly in a U shape around the chip leaving the center of the bottom of the chip free to solder to with my thick copper traces. Note: the thick copper traces will be cut out with scissors from a roll of .2mm copper sheeting I bought on amazon which I mentioned a few posts back. Double stacking it wil double its thickness and increase its conductivity both electrically and thermally. Note: in a usual setup with this CSD95481RWJ IC, a multilayer board with a array of vias is used to bring the heat downward off the chip and into another lower layer within the multilayer board where it can then radiate on said layer outward in every direction. In my approach, I use thicker traces than the layers of a multilayer PCB has so I have alot more local copper in play. Then instead of the heat transferring down and then outward in all directions on very thin copper, mine travels down then in a single direction outward away from the IC on that trace. The trace will need to be as wide as possible as soon as possible. I expect to get it from 2mm width - the width of the pad - to 5mm width within a few mm. This rapid transition to a wider width combined with the use of much thicker copper compared to a multilayer PCB's copper thickness of its layers means I should be able to exceed the thermal performance of a multilayer board using my approach. Especially since I also plan to quickly fork off the main traces with bundles of 4 solder wick wire braids that will carry the heat off to a water cooled pipe 4" away. Note: in my attached schematic I only show a single CSD95481RWJ IC because they are all wired up the exact same way. It's just doing it 3 times for each of the 3 phase wires of the BLDC motor. Note: I will use a single electrolytic capacitor per motor controller also not pictured in the schematic.

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #109, submitted 1/16/26 I was randomly talking to chatgpt about how I have been feeling burdened by having to make my own BLDC motor controllers for my robot lately and it randomly mentioned integrated half-bridge power modules as something I could use to cut down on my labor load in making these motor controllers. This immediately stood out to me as something I'd never heard of and something intriguing. I have so far been working on my lowside switch and highside switch which together form a half bridge. Many solder connections have been involved and alot of discrete components are involved. The concept of an integrated half bridge on a single chip - meaning two big power mosfets and all the drive circuitry for those power mosfets all condensed into a single chip would be a huge reduction in size and component count as well. So I researched if any are able to do 8v 30a for my 2430 BLDC motor's needs. Turns out there are some out there. At first I was looking at Texas Instruments CSD95377Q4M Half-Bridge Driver (30?A) which can do 30a continuous so perfect for me. However, I didn't want to lock myself into a single vendor chip that may one day be discontinued. I prefer something ubiquitous with many competitors making it that can be purchased from aliexpress. Something commodity level. This way I future proof it and don't have to worry about any one manufacturer discontinuing parts I'm using and prices soaring because of that or simply the part becoming unavailable. So after a bit further digging I found CSD95481RWJ QFN chipset on aliexpress sold by several vendors and one was under $1 each. So it is equivalent to two power mosfets plus all drive circuitry for each power mosfet all for under $1. This one also has 60a continuous rating. It is only 5mm x 6mm in size which to me is insane. This is so much smaller than the setup I've been working on yet just as powerful. They are usually used for tiny buck converters and used directly on videocard PCBs and in servers and in automotive PCBs and much more. In any case, using 3 of these half bridge chips you can drive a BLDC motor. The consolidation of so many parts into such a tiny package is truly blowing my mind. So I ordered 60 of these chips - enough to drive 20 BLDC motors. I am leaning toward using these for all my motor controllers if working with them is easier than working with discrete components like I have been. They are cheaper to work with I think - I'd have to run the numbers on that though. They even have built in temp sensing we can read in which is a bonus. Their built in current sensing will not work for BLDC motors so I'll still need my shunt resistor current sensing circuit setup external to it but that's ok. All in all these appear to be a game changer in terms of reducing part count so less potential points of failure and also reducing board footprint so miniaturizing my electronics even more which is very good for us. I'm still needing to work out now how I want to hook these up in terms of PCB making for it and any discrete external components needed to support it. It is also top cooled which is interesting. I'm envisioning using silicone thermal adhesive to glue on a copper pad that has my braided solder wick wires already soldered to it. These will carry the heat away to my water cooled pipe system.

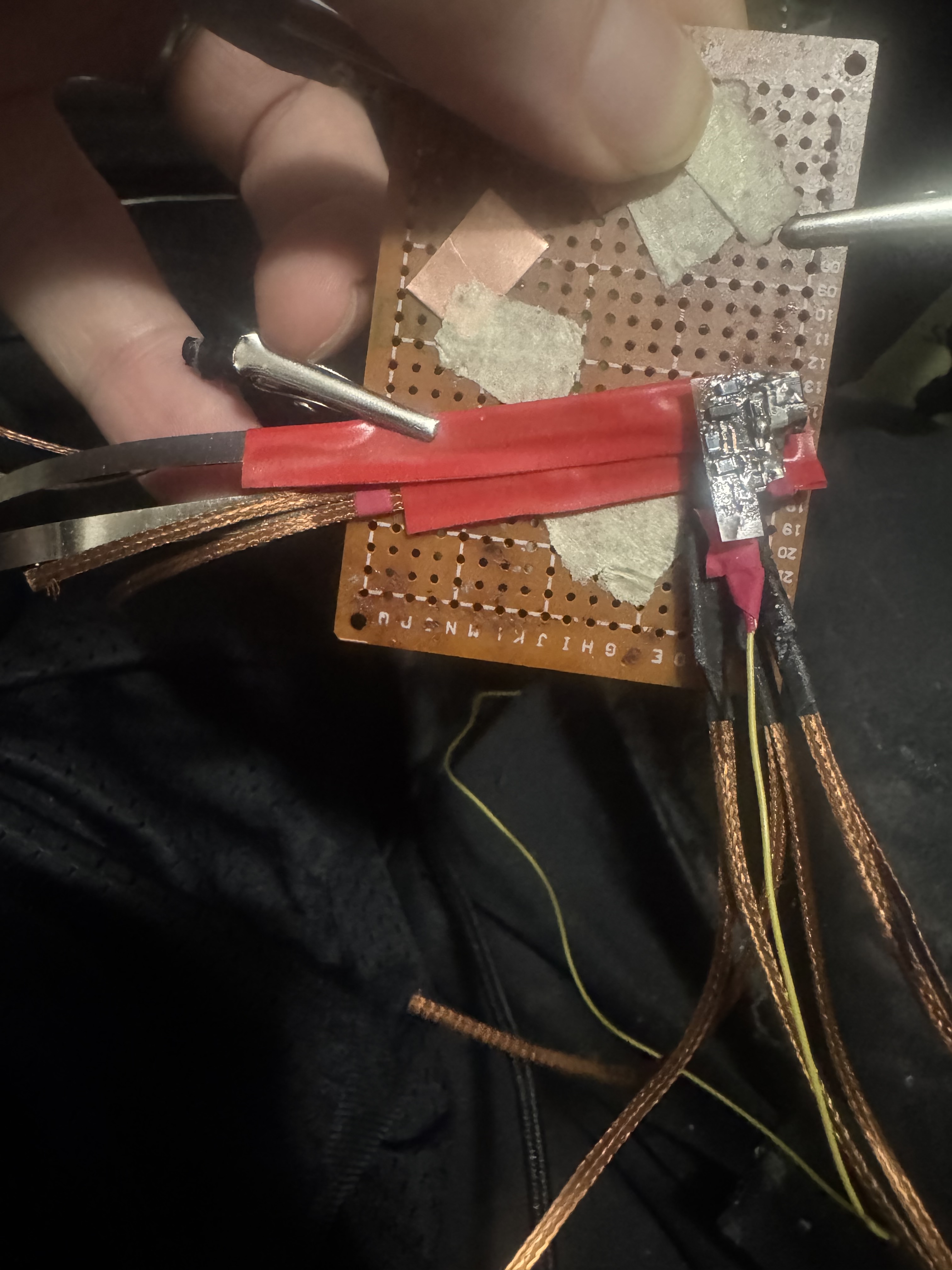

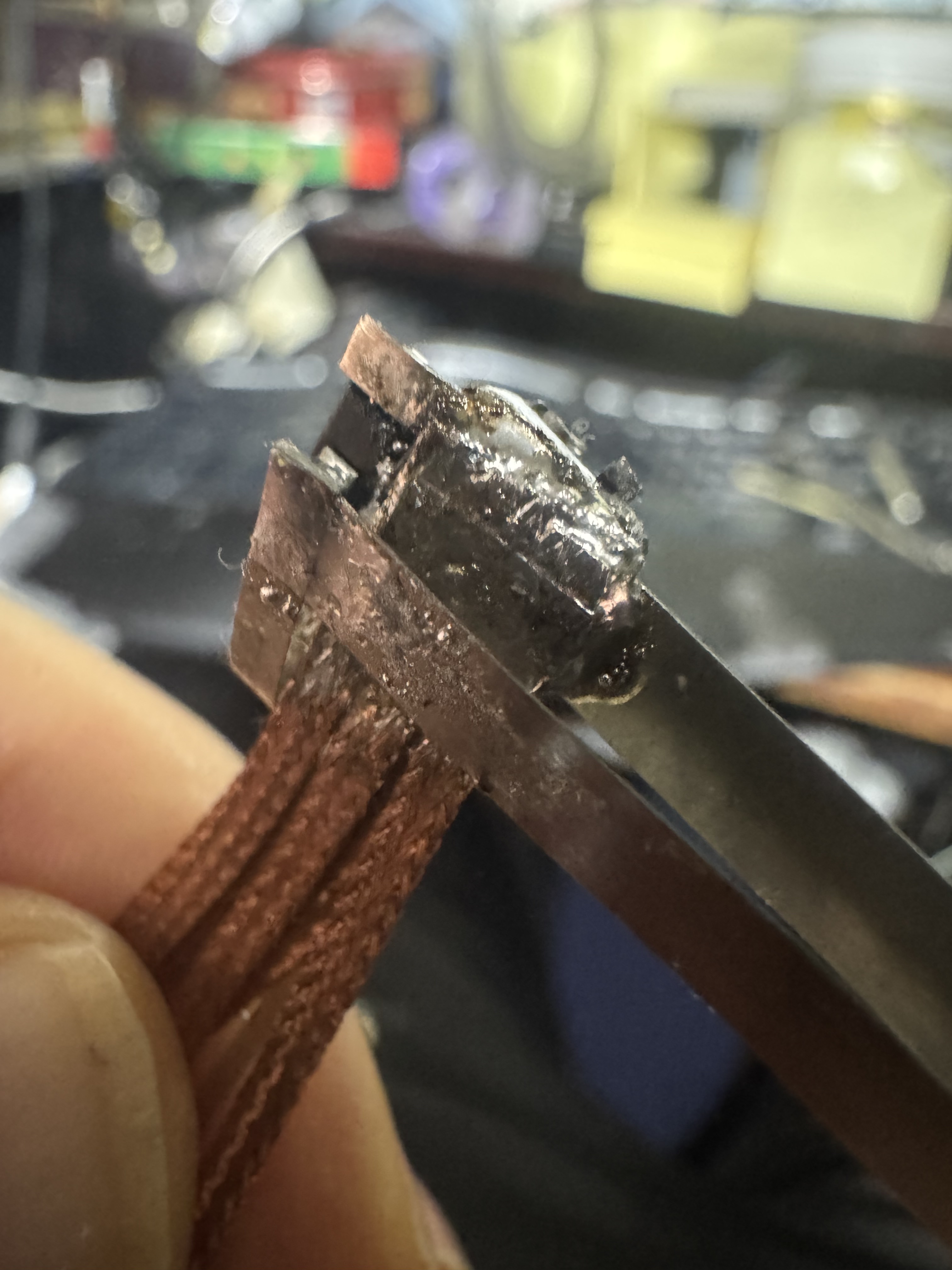

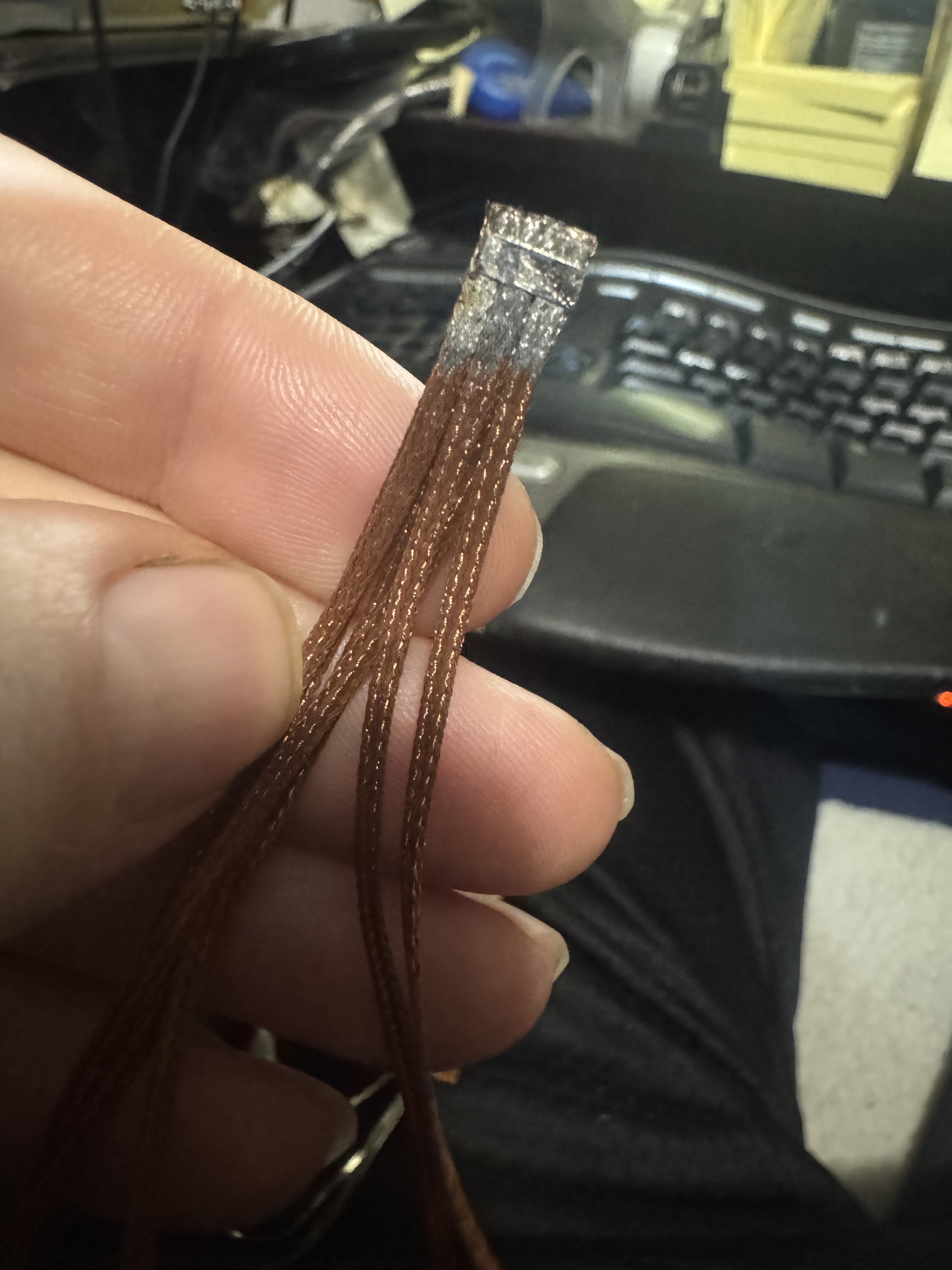

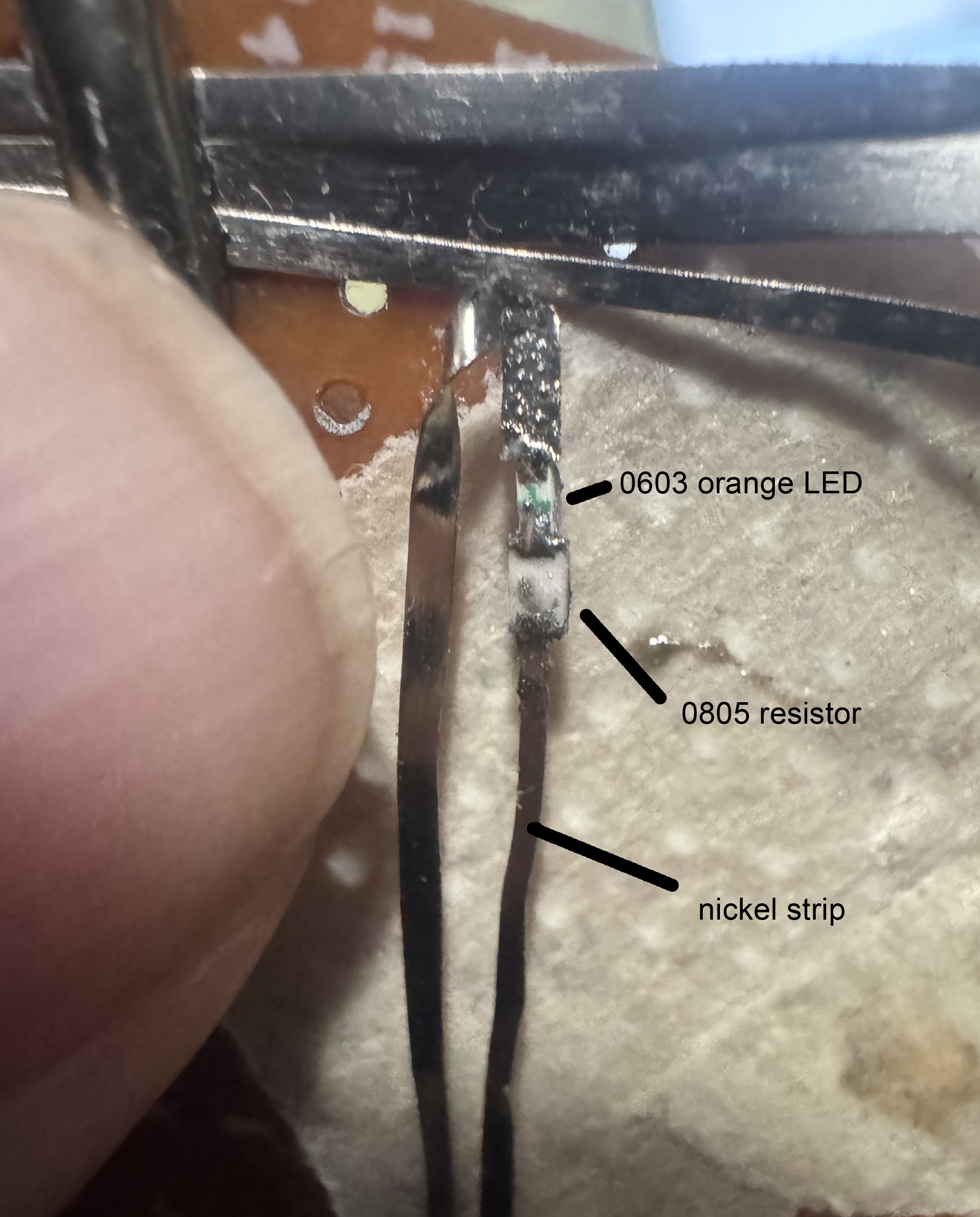

I'm kind of amazed that nobody really seems to use these for BLDC motor controllers. They seem perfect for it. Maybe I'll start a trend. Assuming I don't find out the hard way why they are never used for this application! note: the full product title: "(5pcs)100% original New CSD95481RWJ 95481RWJ CSD59950RWJ 59950RWJ QFN Chipset" note: for my previous BLDC motor controller design I was needing to use 6 digital IO pins to drive a single BLDC motor controller's 6 power mosfets by way of their control circuitry. But for a BLDC motor controller design using 3 CSD95481RWJ H-bridge chips, I will only need to use 3 digital IO pins on the microcontroller. These CSD95481RWJ H-bridge chips use a pwm pin that is a tri-state pin - you can have high, low, and floating as the signal you send to it from your microcontroller. Digital output high and low are the usual digital output modes but the floating mode you do in your code by configuring the pin to be a digital input pin which makes it a floating pin. These 3 states fed into the chip makes it either give you V+ as its output or V- as its output or just off/floating as its output. This corresponds perfectly to the normal h-bridge 3 states we'd be using with our discrete components previous microcontroller design. So this savings in total digital I/O pin usage on the microcontroller means you can drive more motors per microcontroller in theory which is pretty cool. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #108, submitted 1/3/26 So I did manage to add a pair of braided solder wick wire as a added layer over the nickel strips of the highside mosfet setup and I insulated that with red electrical tape folded over it. I also insulated everything else in sight for the most part. I lost the original control circuit so I made the replacement flat flex pcb style which should be more robust. I also added a yellow 30ga wire for the 20v input line of the gate pin of the main mosfet. I also got my fiberglass window screen mesh ready to be installed to insulate the solder wick wires acting as heatsinks. So this setup is getting close to install ready now but I want to test it again to make sure its still working after all the major changes and messing with it so much.

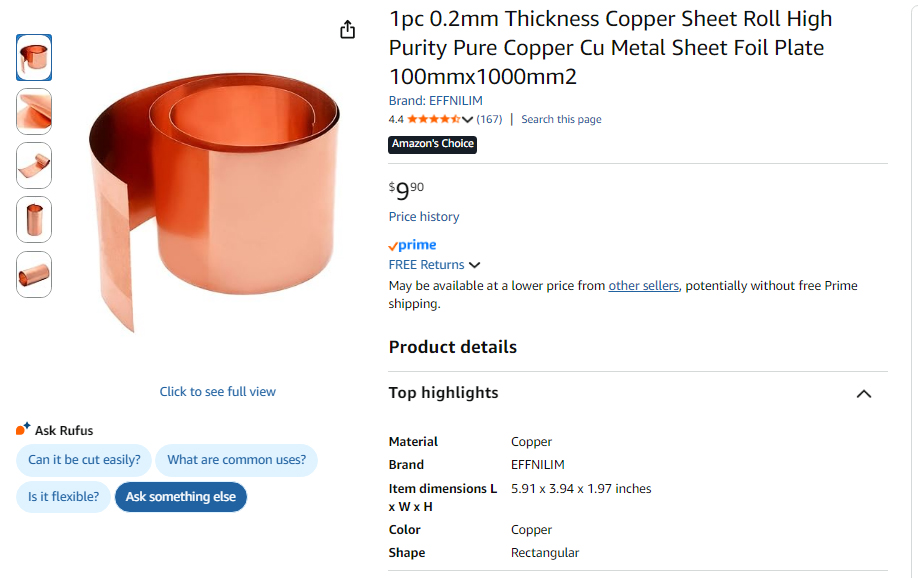

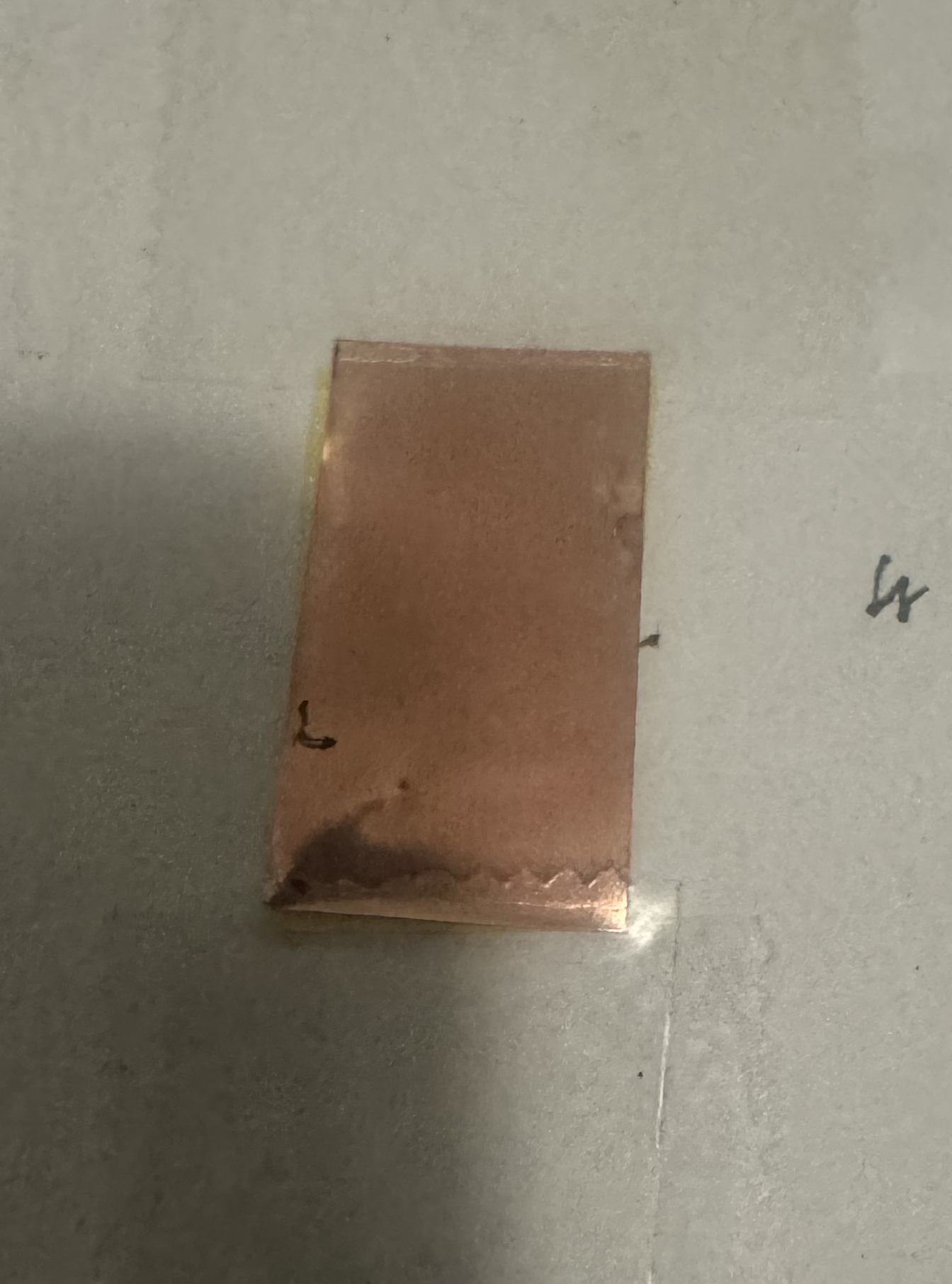

On another note, I noticed that stacking the 0.1mm x 4mm x 100mm nickel strip plus braided solder wick to reduce resistance and increase conductivity made the lines a bit thicker than I'd like, especially after adding tape. So to resolve this I decided to roll with 0.2mm x 6mm x 100 mm hand cut out strips of pure copper plate. I was not aware of this option before but I was able to find copper in .2mm thickness in a roll on amazon that I can use for this. With this thicker size and the much lower resistance of copper I should be able to run 30a through it with less than 1w of waste heat which is great. And this will still give me a way thinner result than what I used on this first one while lending lower resistance by getting rid of nickel strip entirely for the high amp stuff (aside from the shunt resistor nickel strip which I still plan to keep).

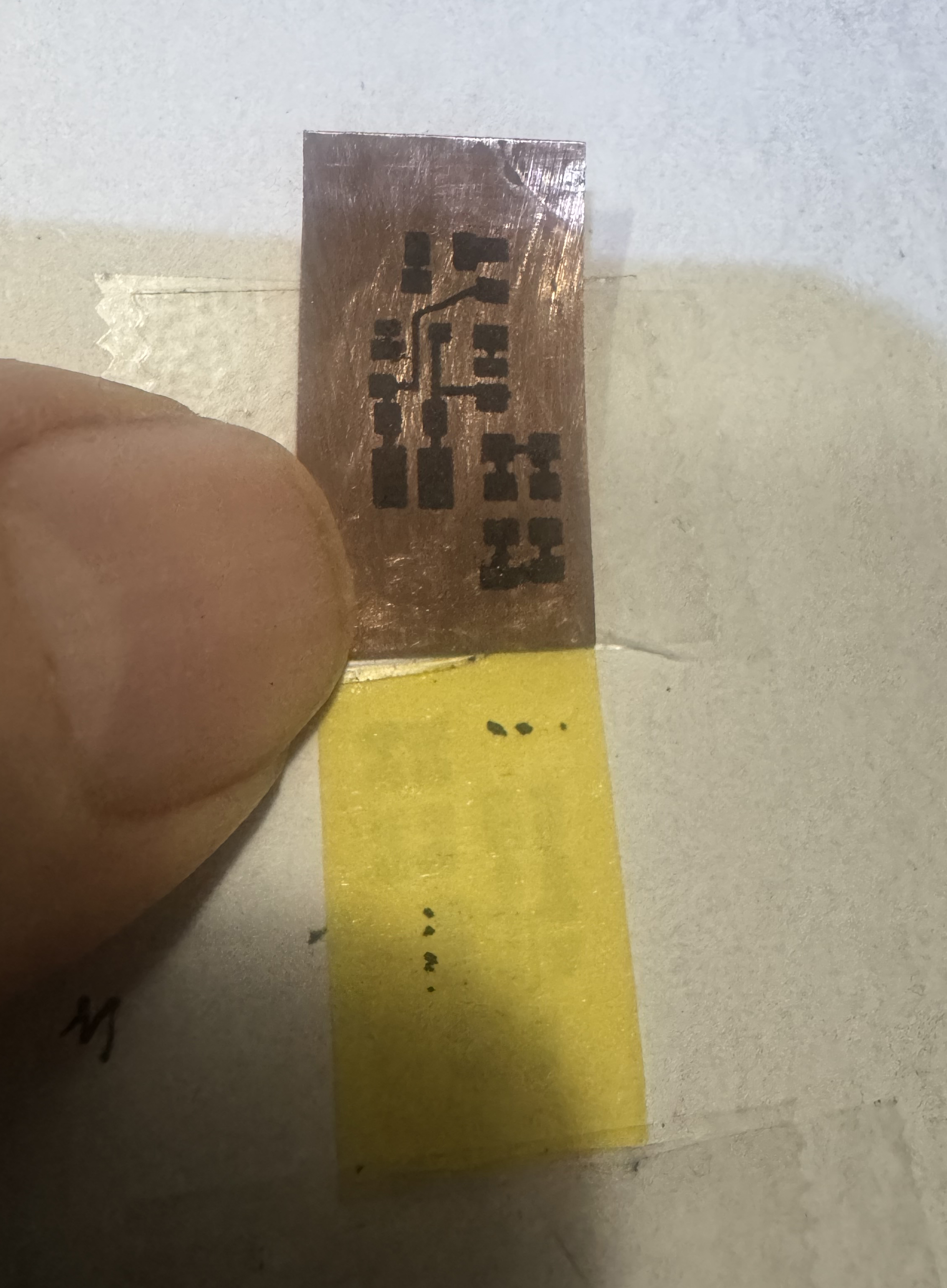

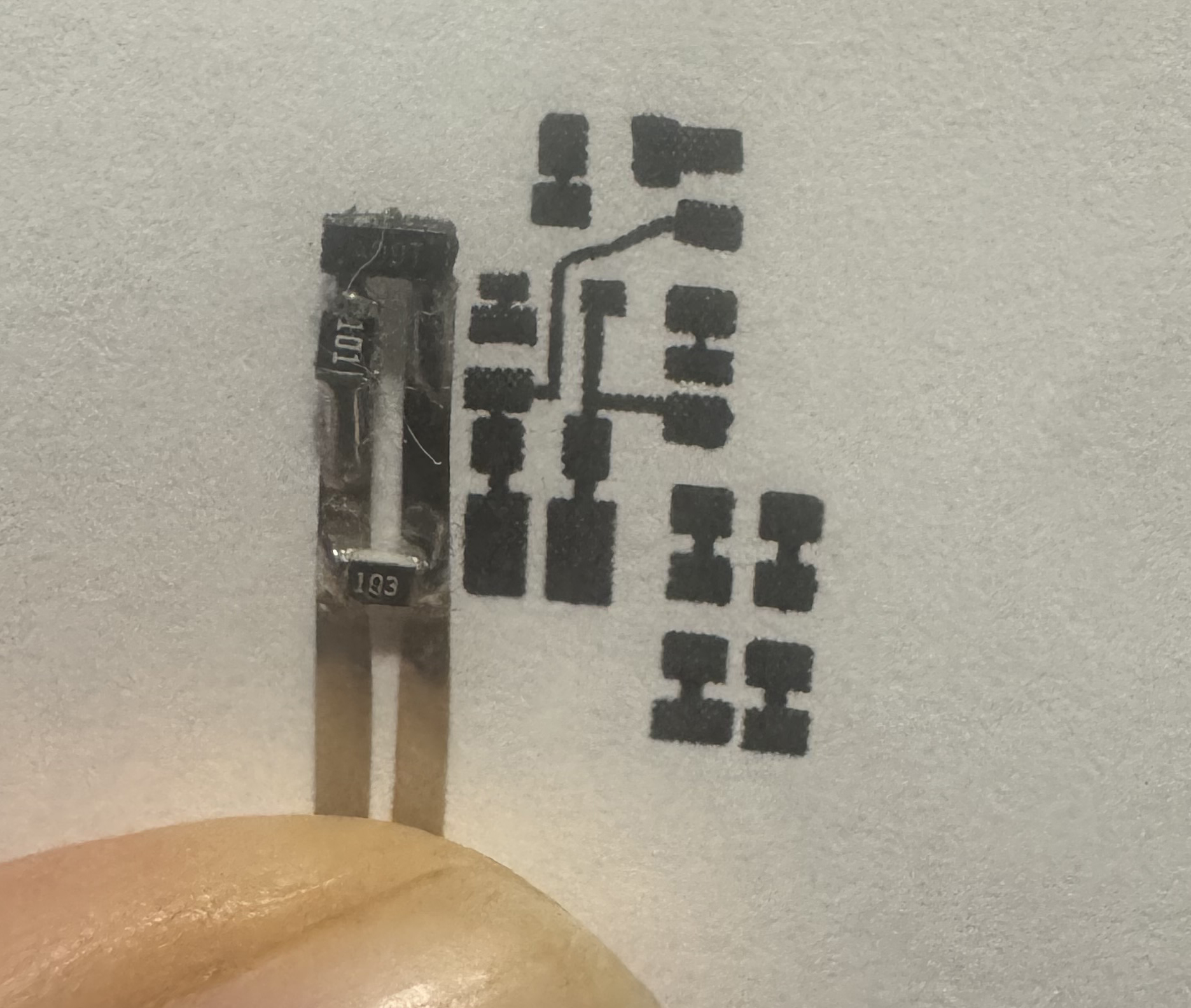

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #107, submitted 12/24/25 Well I tested printing directly onto Pyralux copper and it was a massive failure. Not even one spec of ink stayed on it and the print came out a inch off the location of the copper. Chatgpt said this is because copper can't hold a electro static charge long enough to take ink onto itself or w/e. Ah well I can fall back to the method I already used successfully. On that note, I realized printing my blue circuit is bad since a black and white printer won't print as densely and darkly a blue thing as it would a black thing so I have to make my circuit black before printing it. Also I should set my dpi to 600 dpi instead of 1200dpi which will create denser thicker prints for better transfer. Also I should select label paper instead of heavy paper which will work better. Also using Lumicolor Straedler pen is not good as it can be undercut easily supposedly. Better to use oil based marker instead. So I ordered that in 0.3mm tip. These are all improvements chatgpt suggested and I plan to use when printing onto the pcb transfer paper and hand touching those up if needed. I'm getting ready to make a bunch of flex pcbs for finishing this motor controller. I already started doing it. Another disaster happened to me as well: my highside circuit I just soldered the solder wick wire onto, when I was analyzing it closely on the front I noticed that excess solder from the drain side of it oozed and dripped toward the front side of it and attached to the gate pin! I heated up that attachment point from the front side and my capacitor and resistor from gate to source both came off from the heat! Anyways I heated it up to remove that short circuit and used a xacto knife to wedge between the gate pin and back of mosfet's drain pad which had a solder bridge. I got through the bridge successfully but now have to redo the gate to source resistor and capacitor. Ugh! Two steps forward one step back. Then while inspecting and cleaning everything I moved the control circuitry a bit too much and it broke off for the 3rd time! So that has to be done again. This time I'm using flat flex for it. I've had it with the non flat flex variant breaking. The flat flex is way more solid mechanically. So that's a redo needed. Ugh. Then to top it all off, the solder wick braids recent idea I had to electrically isolate their run near to the mosfet so that they aren't live for very long - which had to do with wanting to eliminate any short circuit risks in their longer run as well as remove any potential for antenna affects - yeah... well after cutting them all in half to do this transition idea, as I was doing it, I realized the surface area where the hand-off takes place between one section of solder wick braid and onto the next seems very small to me (2mm wide by 6mm long) and it seemed to me that the passage of heat across this tiny bridge of thermal tape might be severely compromised and would depend on how tight I made the squeeze of the two pieces of solder wick braid together as well. And I'm not sure I can clamp it tight enough with just tape wrapping it firmly. And if it gets quite hot I'm concerned electrical tape will get gooey and come loose over time and not hold it well. I'm not sure how tight kapton can wrap things I've never used it before so I'm inexperienced with using it and trusting it is hard without experience working with it. This all cumulatively gave me enough doubt that I said heck with it, I'm going to revert to the former plan to just run it live over to the water cooled pipe 3-4" away and use the thermal tape at that junction point where it wraps the pipe. This ensures alot of metal volume is directly tied to the mosfet which means more heat sinking directly with little risk of trapping heat near mosfet - which could happen if my thermal tape junction of copper braid to copper braid were to fail for example by being pulled apart by accident for any reason. Too much risk there IMO. And the risk of a short on account of live wiring it for 3-4" with the live wire sheathed in window screen to emit heat freely but not touch anything I feel is low enough risk IMO. So whatever route I choose has tradeoffs and I feel reverting to my former plan is more robust and foolproof thermally with some minor electrical risks that are mitigated by fuses and careful execution in general. So yeah I had to solder the cut pieces of solder wick braid back together again which was another pain. Note: the next time I solder the heatsink braids onto the drain I plan to use less solder paste so it doesn't ooze and drop forward onto the front circuitry on the front face of the mosfet by accident. I also plan to insulate the front side's circuitry beforehand so even if solder did ooze that way the insulation barrier would prevent short circuits and make the oozing no big deal in theory. So yeah it was a tough session but I learned alot from the mistakes etc. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #106, submitted 12/23/25 So it hit me that having these braided solder wick wires live all the way to the water cooled pipe distal attachment point is not necessary. And could cause some EMI or noise related issues that is avoidable if I do the following: I can simply cut them off 1/2" from the mosfet, stick thermal tape on one face of the cut off stubs, then stick the rest of the braided solder wick wire run against that thermal tape, then wrap this joint tightly with electrical tape. Finally we then electrically insulate the braided solder wick that is live but leave the braided solder wick section that is now no longer live completely exposed on the duration of its 3"-4" long run from near the mosfet to the water cooled pipe. This way we have electrical isolation near to the mosfet, no antenna effect, no need for window screens now, and no live wires hanging out that aren't properly insulated. Thermal conductivity is reduced negligibly with this solution. This should be trivial to implement as well. It's the perfect solution here and very fast to implement. It may even be slightly less work than dealing with window screens would have been. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #105, submitted 12/22/25 I used my jumbo Weller W100P soldering iron to attach my 6 solder wick braids to the back of the highside mosfet today and it attached instantly without a hitch. I used low temp solder paste liberally between the two on both surfaces then with my left hand smashed then together with the tip of a xacto knife pressed down onto the solder wick braids from the back. Then I brought in the giant soldering iron and it liquefied the solder in about 1 second despite all that metal involved because it holds such a massive amount of thermal energy that it can deliver on demand very quickly. Such a easier time than trying to do bigger soldering jobs with a micro tip regular soldering iron which often ends with cold joints and stuff. Also since the liquefication went so fast nothing nearby desoldered which is a huge plus.

Next up: add the solder wick braids to the underside of nickel strips to lessen resistance there and then insulate this highside switch assembly and install against motor and start finalizing wire run plans. Then I can rinse repeat this for the lowside switch assembly. Then I'll have one of the 3 half bridges done for the motor controller. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #104, submitted 12/21/25 I did some research of some loose ends today on chatgpt and discovered that my .1mm x 4mm x 60mm sections of nickel strip on my bldc motor controllers that run from the battery to the motor controller mosfets and from the mosfets out to the motor are too high in resistance and at 30a they would within a few seconds get so hot that they would desolder my low temperature solder paste. So to solve this I will be placing two side by side solder wick braids hugging the underside of the nickel strips which will lower resistance so much that temperature will stop being an issue. They will be a combined .1mm x 4mm x 60mm. Then on future mosfets for this portion I will just use the solder wick braids for this section and not use nickel strips at all because they add too much resistance under this high of amp flow. The 2430 BLDC motors are rated to 25a continuous so my conduit has to also handle that easily without overheating. Another really cool discovery I made today was on the topic of measuring current. I'd been putting this off till now but finally got around to deep diving it with chatgpt and discovered something shocking. So basically it was saying to use a shunt resistor inline with the ground side running from the motor controller to the battery. All the current of the motor controller (30a on the high end) will pass through this resistor as its only path. The special thing about a shunt resistor is that its resistance is so low that it doesn't affect voltage or amps a whole lot. I asked chatgpt if I can use nickel strips as my shunt resistor since a smd shunt resistor it said would overheat fast at 30a. It said yes! So I'll be using a .1mm x 4mm x 30mm section of nickel strip as part of my wire run going from the motor controller back to the battery on the ground side. This will act as my homemade shunt resistor. Now the way the arduino will read the amount of current is the analogue input pin will feed into the upstream side (closest to motor controller) of the shunt resistor section of nickel strip and the arduino ground will attach to the downstream side of this nickel strip shunt resistor. It will measure the tiny amount of voltage drop that occurs on account of the shunt resistor's resistance. What is really cool is that the voltage drop changes at this resistance and amp level are read granularly enough by the Arduino analogue input pins that I don't even need to amplify them to read them in meaningfully. Some things like strain gauges provide such tiny resistance changes that you have to use a OP AMP amplifier to be able to read the changes in with your analogue input pin of your arduino to detect them meaningfully but in this case, the resistance changes are large enough and the analogue input pins are granular enough to be able to read them in without any amplification. This means reading in the current for my motor controllers requires ZERO components! It's literally just nickel strip which I already had for the battery tab making and some jumper wire or w/e to take in the readings and that's it! No parts to buy. I had bought some hall effect based current sensor kits and they are not needed at all. I wasted my money on them in the past because I did not know about this shunt resistor option at all at the time. Had I known I would have never bought hall effect based sensor kits - a waste of money. Not to mention they were relatively huge whereas this takes up like practically zero space to measure a shunt resistor section of conduit between the battery and motor controller. So it's awesome news! Note: the current sensing is meant to tell my control system anytime a new unexpected load has hit the motor so it can slow down the flow rate of electric to the motor to prevent burning out something for example or it can also detect any kind of snags or w/e anything getting stuck. It can also help monitor amp flow for the sake of holding the motor in place with stall current kept low enough to prevent overheating etc. It can also act as collision detection if trying to monitor its interactions with its environment and know if something has hit something - which is insanely useful for situational awareness. So it's extremely useful and basically not even optional frankly. To now know that adding this feature is free and super easy to implement and will take up practically ZERO extra space is very exciting to me. Note: my diy shunt resistor (.1mm x 4mm x 30mm section of nickel strip) will have a .005 ohm resistance which is pretty much perfect for my use case it seems (unproven but chatgpt sounds sure of it). It will enable me to monitor the range of 5a to 30a and detect a change in amperage with like 1a granularity. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #103, submitted 12/19/25 I have two great breakthroughs to announce. First, it suddenly occurred to me that I don't have to print onto PCB transfer paper and then transfer that over to the copper clad Pyralux flat flex PCB but instead I can simply tape the copper clad Pyralux flat flex PCB directly onto my envelope and feed that through my laser printer directly. See, I previously ruled this out when originally researching this stuff because I was planning to use FR-4 PCB which is not flexible nor flat enough to feed through a printer directly. However, now that I am using flat and flexible blank PCB there's no reason not to feed it straight into my laser printer that I'm aware of. Now I haven't tested this but if it works it's a game changer. Will make DIY PCBs that much faster and more streamlined to make! Next, on the subject of attaching the 6 solder wick braids to the mosfets, I was struggling going through the various methods whereby I can tightly clamp it to the mosfet drain and add electrical isolation barrier to the connection point. It's very tight spacing and has to be a very tiny clamping mechanism and the clamp from most directions would have things getting in the way of any clamp design I visualized. It was a nightmare problem IMO. However, my solution I came up with today is game changing: I will simply solder the braids directly to the mosfet drain! This will maximize conductivity off the drain into the braids due to the metal on metal direct connection and eliminate all need for any kind of clamping at all there. Unfortunately, this will make these braids live electrically, but it occurred to me that this is not a big deal. I will simply wrap them in fiberglass window screen to allow them to have great airflow and breath-ability for emissivity of the heat they will be wicking off the mosfet drain and the fiberglass window screen will also act as a physical barrier to them contacting other live metal parts. Window screen is also non-conductive and has good abrasion resistance IMO. I don't anticipate these short wire braid runs to have much contact with anything as they are going to be making short runs from the motor to the water cooling pipe anyways and the exoskeleton mesh that holds up the rubber skin will create spacing and cushion contact bumping or w/e coming from the outside. All in all I think this is a safe solution for the most part and we'll have fuses anyways to prevent major problems in the low risk event of two neighboring live groups of solder wick braid breaking out of their window screen and contacting eachother thereby shorting the circuit. I just see this as highly unlikely but it's covered by the fuse in any case. That all having been said, the electrical isolation barrier stage we now can place at the location where these solder wick braid ends attach to the copper liquid cooling pipe. There at that attachment point I'll put my electrically isolating thermal tape between the solder wick braid and the pipe and clamp things down by tightly wrapping it in electrical tape at the connection point. This is trivial to achieve compared to doing this at the location of the mosfet drain. So we kicked the electrical isolation and clamping problem further downstream than the mosfet drain connection point in order to make the problem a piece of cake. Note: chatgpt said I should tin the braided copper solder wick to prevent oxidization of it which would potentially lower its emissivity. Not sure I agree on this though but I may do it just to be safe we'll see. I'd use MG Chemicals Liquid Tin to do this which I already have on hand for tinning circuit boards. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #102, submitted 12/7/25 Ok here's the populated board. I tested it with 5v positive and ground and the LED came on so it is for sure not shorting and has continuity so is most likely all working. The next test will be the full lowside switch with this board acting as the drive of the main mosfet for the switch. And once that is validated we can test the entire half bridge (both high and lowside switches). If that checks out, it's all rinse and repeat to make the full motor controller (which is just 3 total half bridges).

note: I just wanted to hold off on attaching the heatsink for the moment as I validate the first half bridge and once that checks out electronically then I'll get the heatsink attached and go from there. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #101, submitted 12/6/25 I successfully made a viable flex pcb on my second attempt. I started by printing the circuit onto a mailing envelope using my laser printer. Then I taped a piece of toner transfer paper for pcbs shiny side up directly over where the print on the envelope was. This way I could use just a tiny bit of the expensive toner paper and know the printer would hit that exact spot again when I reload the envelope in the same spot.

The print landed right on the toner transfer paper according to plan. I then sanded with 400 grit sandpaper the Pyralux flat flex PCB copper blank and wiped it off with a alcohol prep pad. These actions clear any oils and oxidation and give more bite for the toner to cling to the board better. I then taped directly onto this toner transfer paper print the Pyralux flat flex pcb copper blank. No need to even take it off the envelope. Just taped it right over it and fed the whole sandwiched assembly through my laminator a few times envelope and all.

When I peeled back the Pyralux flat flex PCB my laser printer's toner was indeed transferred over to the Pyralux flat flex PCB's copper.

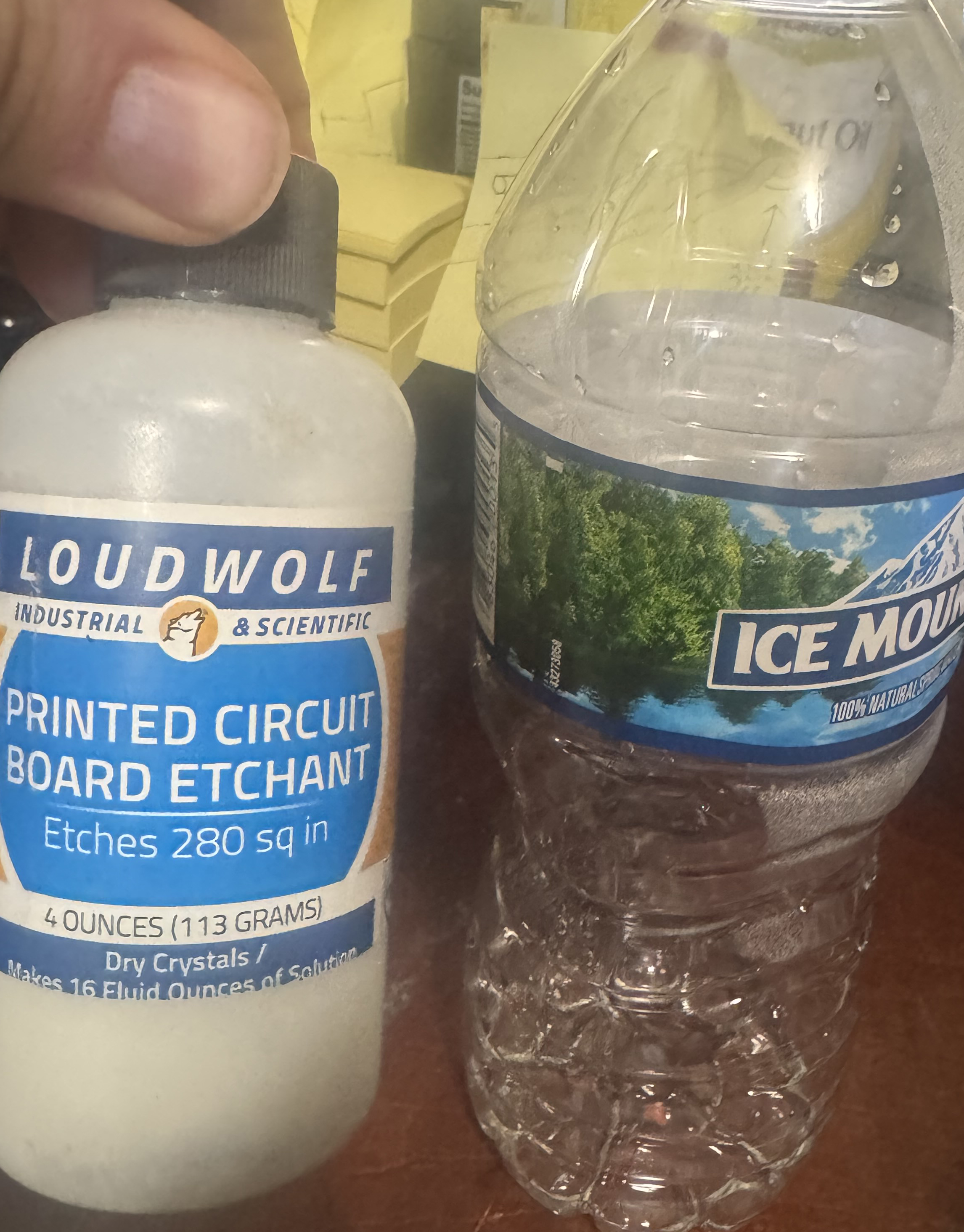

I prepared etchant solution mix of 1 part etchant powder to 4 parts water. I just eyed this roughly and think I did not put in enough echant which causes undercutting of the traces under the toner and slower etching. Lesson learned.

I mixed it in a silicone earplugs container. My aim was a small container to make a smaller batch of the etchant to cut down on etchant used since I'm only doing a very small PCB.

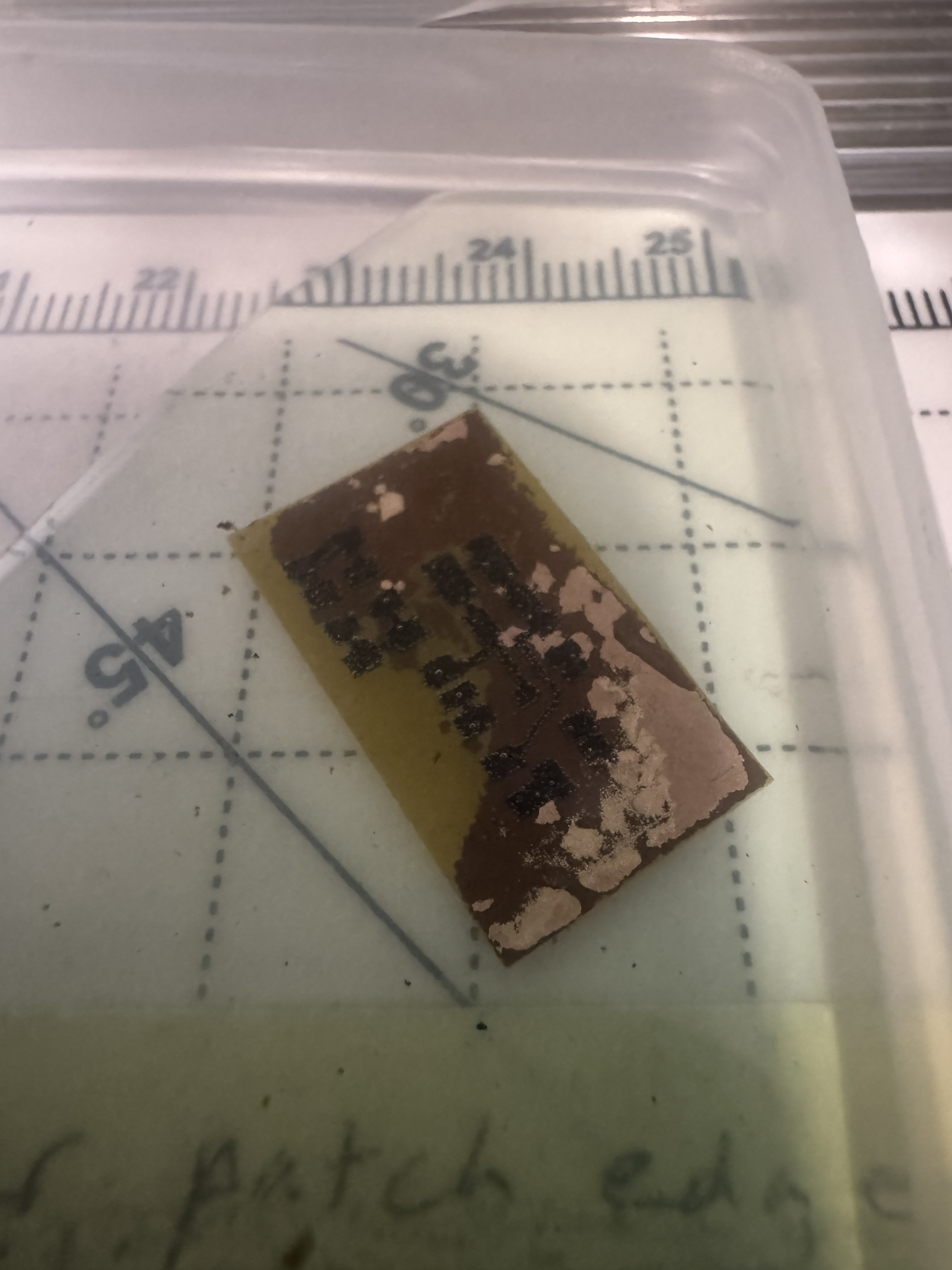

The first board I left etching for a couple hours unattended which was a mistake. It was unusable. A ton of the copper under the toner was missing which is called undercutting. I left it etching for too long which causes this. The second board came out pretty good. But I used the exhuasted etchant from the first board which was already too diluted and so the results were meh but good enough to use IMO.

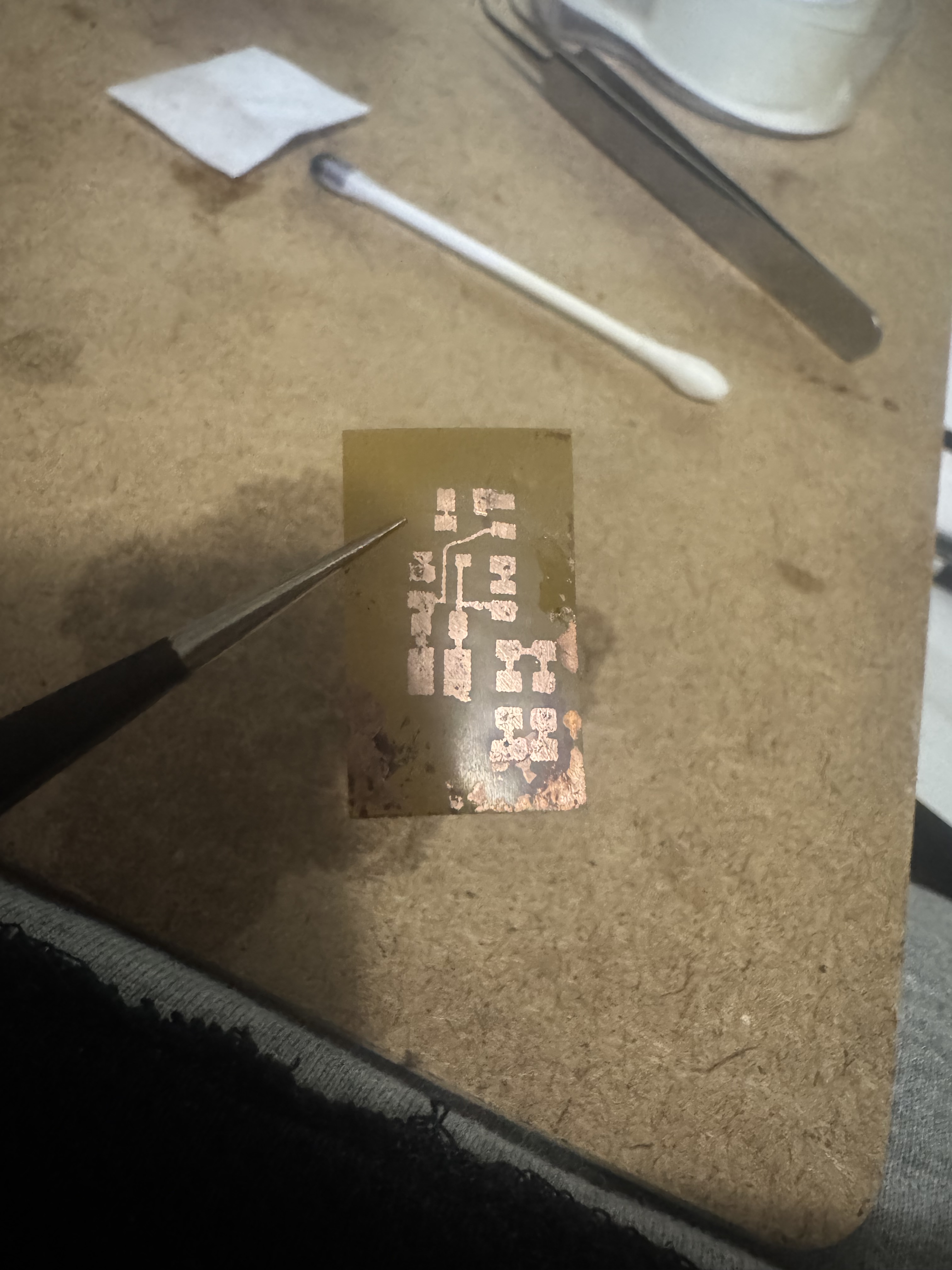

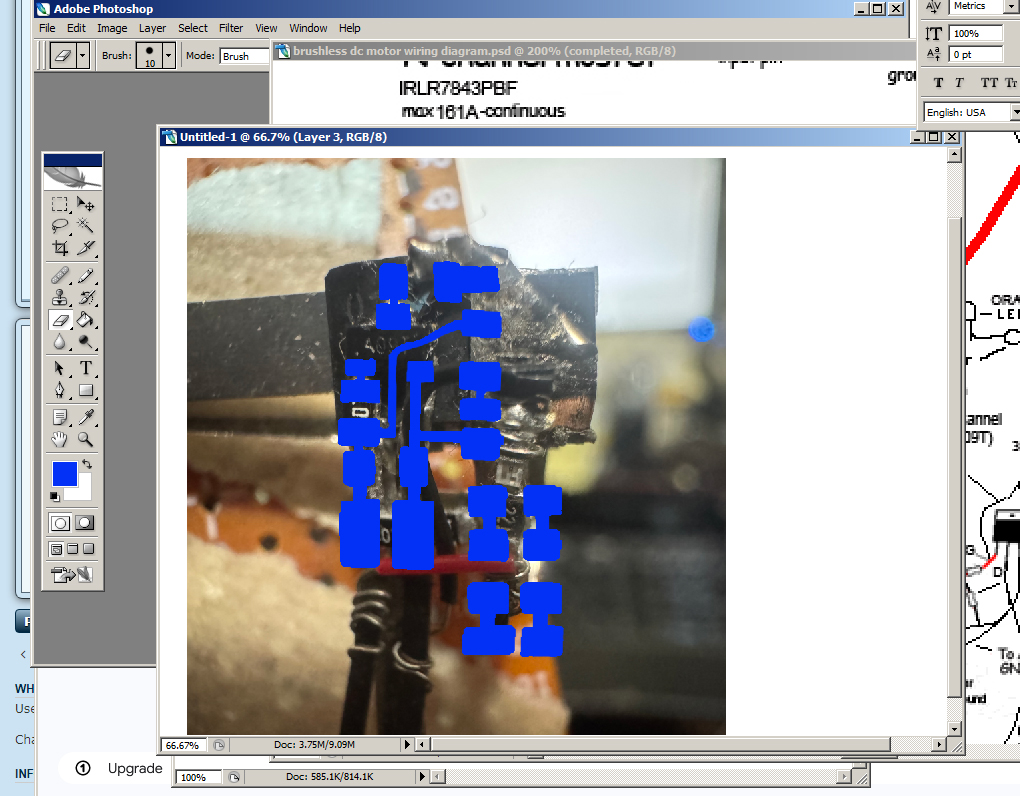

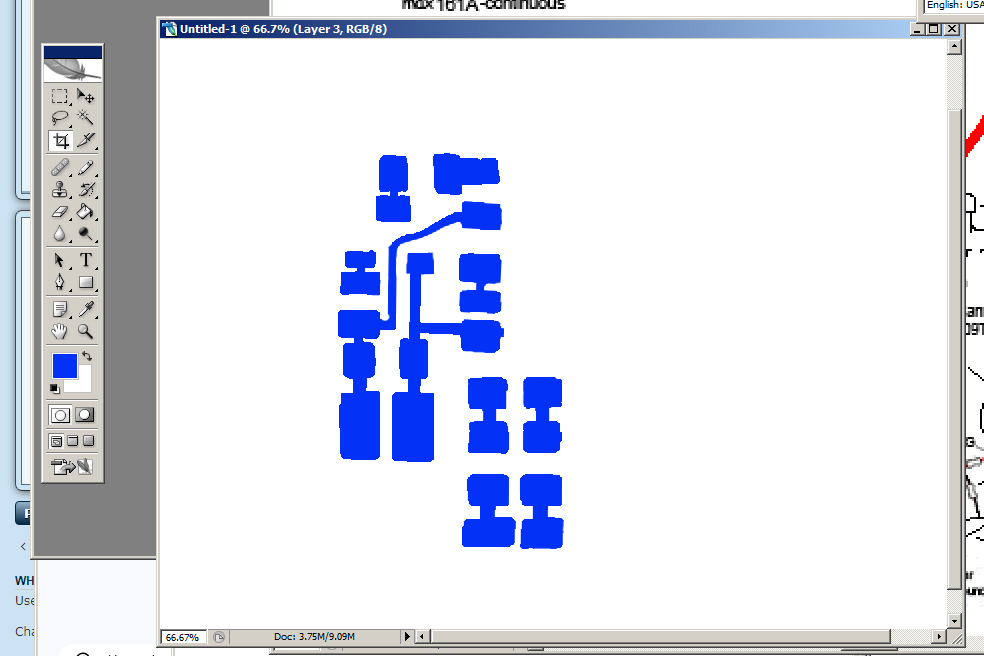

Note: the prints going onto the toner transfer paper are not very high quality and sometimes has missing spots so AFTER transferring it to the copper I used a Straedler permanent lumoocolor super fine tipped pen and magnification to carefully color in any missing spots where the laser printer failed to deposit enough toner or the toner failed to transfer perfectly enough. I used stippling method with the pen - just dotting over and over rather than drawing to get max precision for cleanup of the tiny pads and traces on the copper. Note: I never had to use water to remove the toner paper from the pcb. Just laminating it a few times through my laminator was enough for the transfer to take place and I was able to cleanly peel it away. This meant the toner transfer paper could remain taped to the envelope and be reused indefinitely. I reused it a few times successfully as I dialed in the processes. This is very nice. Saves time for sure. Note: I did attempt to not sand nor alcohol treat the Pyralux copper pcb blank and toner transfer onto virgin copper blank but it did not adhere well enough so I reverted to the recommended sanding and wiping after all. Was worth a shot to save steps but did not work out. Note: I used heavy paper setting in photoshop during the print dialogue settings because the normal print settings were kind of messing up for me. I also think this printer is not very well suited for this. My other laser printer has a "best" quality option and did very nice prints but this one is a cheapo I'm using and only has "fast" quality but worked well enough nonetheless for the most part. Note: I assumed I could use this etchant over and over and over but chatgpt said it gets exhausted and loses efficacy and should only be used once. Some acids people made online you could use over and over but I guess not this type not sure. Note: the acid etchant I'm using says it only releases oxygen so the fumes I guess are not bad like some other kinds of etchant - correct me if I'm wrong on that though. Note: I used a q-tip and lacquer thinner to remove the toner after the etching was done. Note: use black, NOT blue for circuit in photoshop so that it will print more dark (otherwise printer prints the black spotty to lighten it and this means less toner and less good results of traces ouch!) Note: in photoshop during printer settings dialogue, select paper type: labels or heavy (labels preferred); transparency is also a good option? Note: in photoshop during printer settings dialogue, use 600dpi instead of 1200 FastRes (600 dpi gives you thicker, more transferable toner.) Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #100, submitted 12/5/25 So armed with my successful electronic test of my prototype highside switch with driving circuit all passing, I determined now it is sufficiently validated to go through the process of converting it into a printable schematic and doing the whole DIY flat flex PCB making and acid etching process to streamline the development of the rest of the motor controller and most likely many more motor controllers as well. I opted to use photoshop as my circuit making software of choice as I'm very familiar with it and use it often. I first dropped my top view photo of my prototype circuit into photoshop then I redid its layout a bit to make it more compact, moving around copied pieces on the photo to achieve this. Next, I used the pencil tool to color in blue pads and traces connecting all the pieces of it together. I then hid all but this pads and traces layer and printed it several times, tweaking the printing scale until it fit the size of the pieces IRL. 7.5% scale was the perfect fit.

Next, I will need to refresh my knowledge of the transfer paper print and transfer of the ink off of this paper onto the copper clad blank flat flex PCB and then acid etching away all unwanted copper and then removing the ink to reveal the fresh copper traces and pads. Then I can solder all the SMD components onto this. Heck I may even make a solder paste stencil and place components and bake them on. But perhaps just hand solder for now? Not sure. The former is faster in the long run but takes more setup and is quite committing. I'd rather validate my designs even further before going that far. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #99, submitted 12/4/25 I just tested the positive high-side switch portion of the motor controller and everything seems to be working as intended. The section including all parts involved is circled in a bold blue line to indicate the portion I just tested successfully.

One issue I'm having though is that the drain of the A09T attaches to the 100ohm resistor tightly and is a weak point that broke off twice now. Hardly any wiggling at all on the arduino input line and ground line leading into the A09T mosfet causes the drain solder attachment to break off. I am wanting to glue it all down onto the mosfet but I'm supposed to tape the heatsink on under all this stuff so I don't think I should glue it down. I need some kind of backing sheet to glue things off onto (where a PCB normally does this job). Which will provide much needed strain relief at all attachment points. I guess I'm learning the hard way why PCBs are used in general. Without a flat backing plate or substrate of some sort the attachment points between components are vulnerable to flex and breakage super easily. This surprises me.

To perform the test I used one lab power supply set to 20v and one set to 8.07v and used a 18650 lithium battery as the 4.12v to simulate the arduino output pins. I carefully electrically isolated all the metal lines with packing tape for now to ensure no short circuits and then I connected the lab power supply pins to the correct locations with alligator clips. Finally I connected the 18650 lithium battery 4.12v to simulate the arduino turning on the A09T mosfet - I did this using the two nickel strips for this portion joined to the battery with neodymium magnets. If I had a 3rd power supply I could get 5v off of I'd have done that but I didn't have one in arms reach so the battery it was. The LED came on and I tested the output line to the motor was indeed 8.07v. I then disconnected the + side of the battery and verified the line going to the motor was 0V. It was - although if I kept the multimeter on that line longer I noticed it would creep up to like 3.4v but something similar happened on my last test run and chatgpt said this was like parasitic capacitance involving the multimeter or something and nothing to worry about. The main thing is it would START at 0v when I first connected and then rise up to 3v or w/e over time on the multimeter screen and this behavior was ok last time so meh. We're good I think. Where to go from here then? Well I'd say I make the other (lowside) portion of the half bridge and then test the full half bridge to ensure it's all working. I think then my design is validated enough to move into diy flex pcb for some of these portions that are on the layer that goes onto the main beefy mosfets. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #98, submitted 11/11/25 Okay so here I have attached the LED and resistor pair with their 30ga wire wrapping wire onto my highside mosfet's front face. I may add conductive silver paste to the wire wraps in the future if any issues come up there. However, I am wondering if just tightly wrapping it in electrical tape would more or less guarantee the connection doesn't open circuit. We'll see.

I also finished soldering together six braided copper solder wick strands which will act as my heatsink for my highside mosfet. I am still deliberating on how to attach it to back of mosfet in such a way that it will be electrically isolated but thermally conductive. I am leaning toward thermal tape for this.

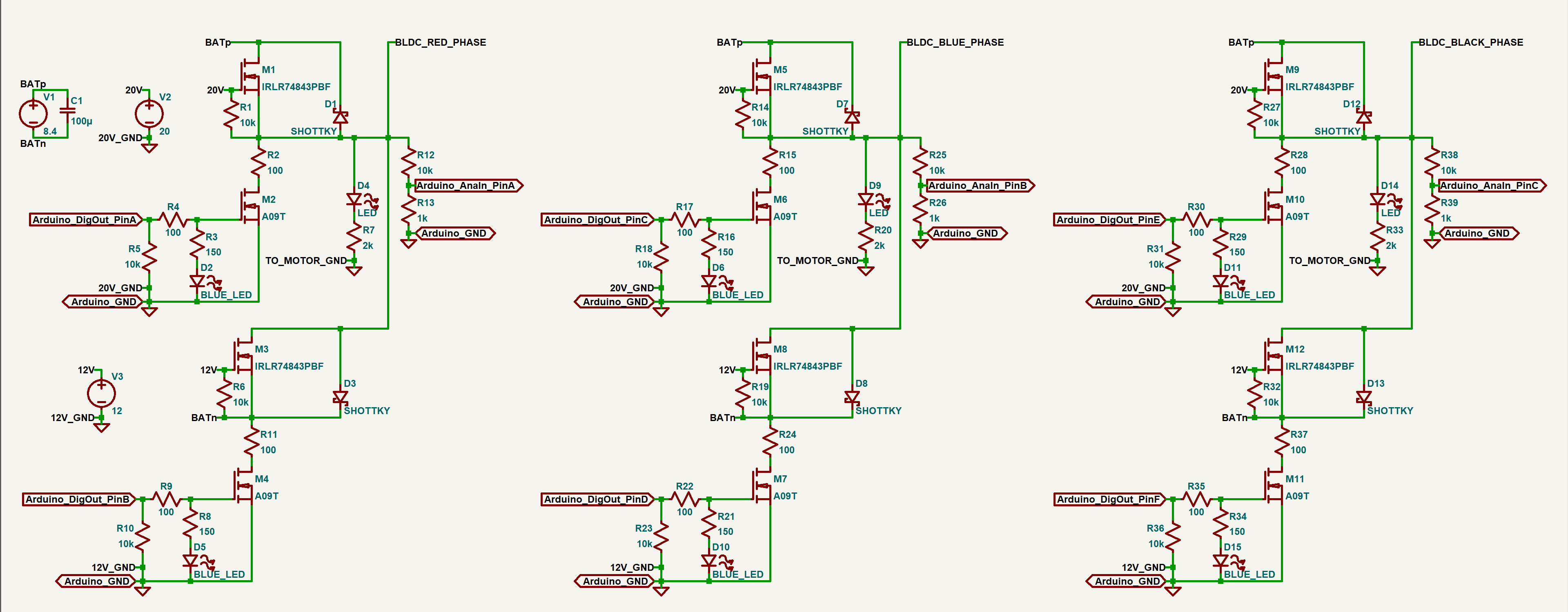

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #97, submitted 11/7/25 Couple updates: An audience member redid my brushless DC motor schematic in the traditional commonplace formatting which for most is easier/quicker to read and understand due to familiarity. So I'm reposting it. It looks mostly accurate although I have since added a 100nF ceramic capacitor between the gate and source of the highside mosfets to reduce ringing issues. Standard practice according to chatgpt. I also changed the LED color to orange because chatgpt said blue would show through the silicone skin more and add a cold inner glow and we want it to look like real skin so no blue. As to why the highside mosfets get a 100nF ceramic gate capacitor but not the lowside, here was how chatgpt explained it to me: -High-side MOSFETs: Their source pin moves up and down with the motor phase (it's not at a fixed potential). During switching, the drain and source both move rapidly, and the gate voltage must track that movement precisely - any ringing or inductive noise can momentarily over-stress Vgs. That's why we add the small capacitor across gate and source: it tames that high-frequency ringing and helps hold the gate steady relative to its moving source. - Low-side MOSFETs: Their source is solidly tied to ground, so the gate always swings relative to a fixed, quiet reference. They don't experience the same "floating" gate drive or large dv/dt transitions on the source pin. So, the gate is inherently more stable, and you don't need that extra 100 nF G-S capacitor. Anyways, here is the audience member schematic:

Here is my updated schematic with the changes I mentioned:

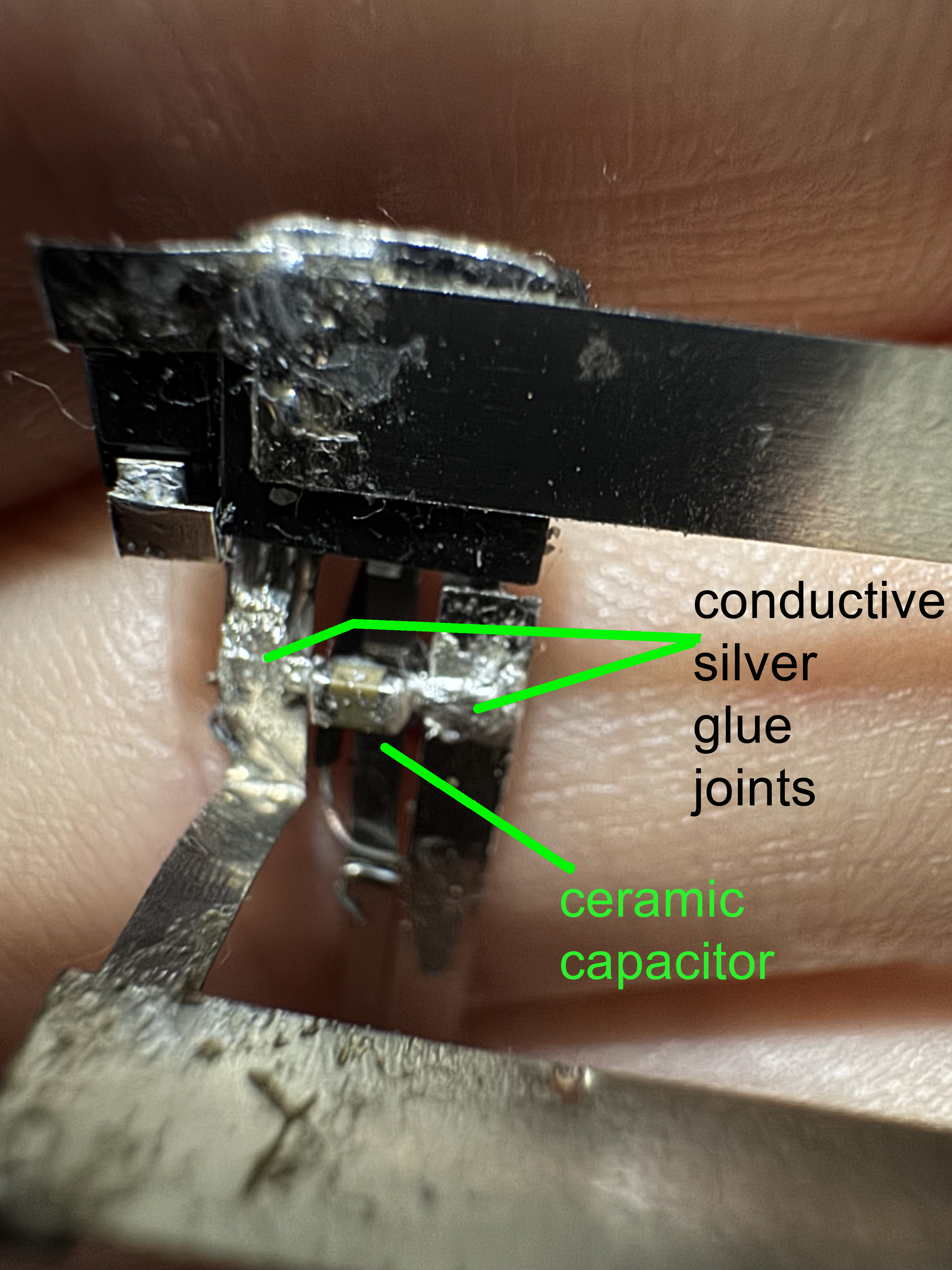

In further news, I tediously installed the new 100nF ceramic capacitor between gate and source of the mosfet. Due to the close proximity to the 10k ohm Vgs resistor and various other low temp solder joints in the immediate vicinity, any heat applied would surely have caused those to desolder and the whole thing to start falling apart so I ended up just soldering nickel strips to either side of the 100nF ceramic capacitor (by itself off to the side) and then used the tip of a sewing needle to apply a tiny amount of conductive silver glue onto the gate and source nickel strips coming off the IRLR7843PBF mosfet and then pressed the nickel strips of the ceramic capacitor into that. I put that in front of a mercury vapor bulb for an hour or so to cure and then applied another generous helping of conductive silver glue over the top of the joint. I then baked that another 7 hours under the mercury vapor bulb again. This photo shows the final result.

It appears to be a solid joint and I think this is a great way to make attachments when you can't use soldering! It might even be better than soldering in some cases from a ease of application perspective but not sure yet on that. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #96, submitted 11/2/25 Ok so I decided to use 30 gauge wire wrapping wire and wire wrap that onto my nickel strips that I connected onto my LED setup then trim off any excess nickel strip. What I like about this is this wire is very fine so it takes up hardly any space and by being able to wrap it on I did not have to apply heat which could have desoldered my smd components by accident. I also like that it is already insulated and color coded so I don't have to worry about insulating my nickel strips the whole run to wherever this connects. To insulate the whole LED contraption here I used packing tape so I can see all my components well but still have them electrically isolated. I just folded the packing tape over the whole assembly like closing a book over a bookmark.

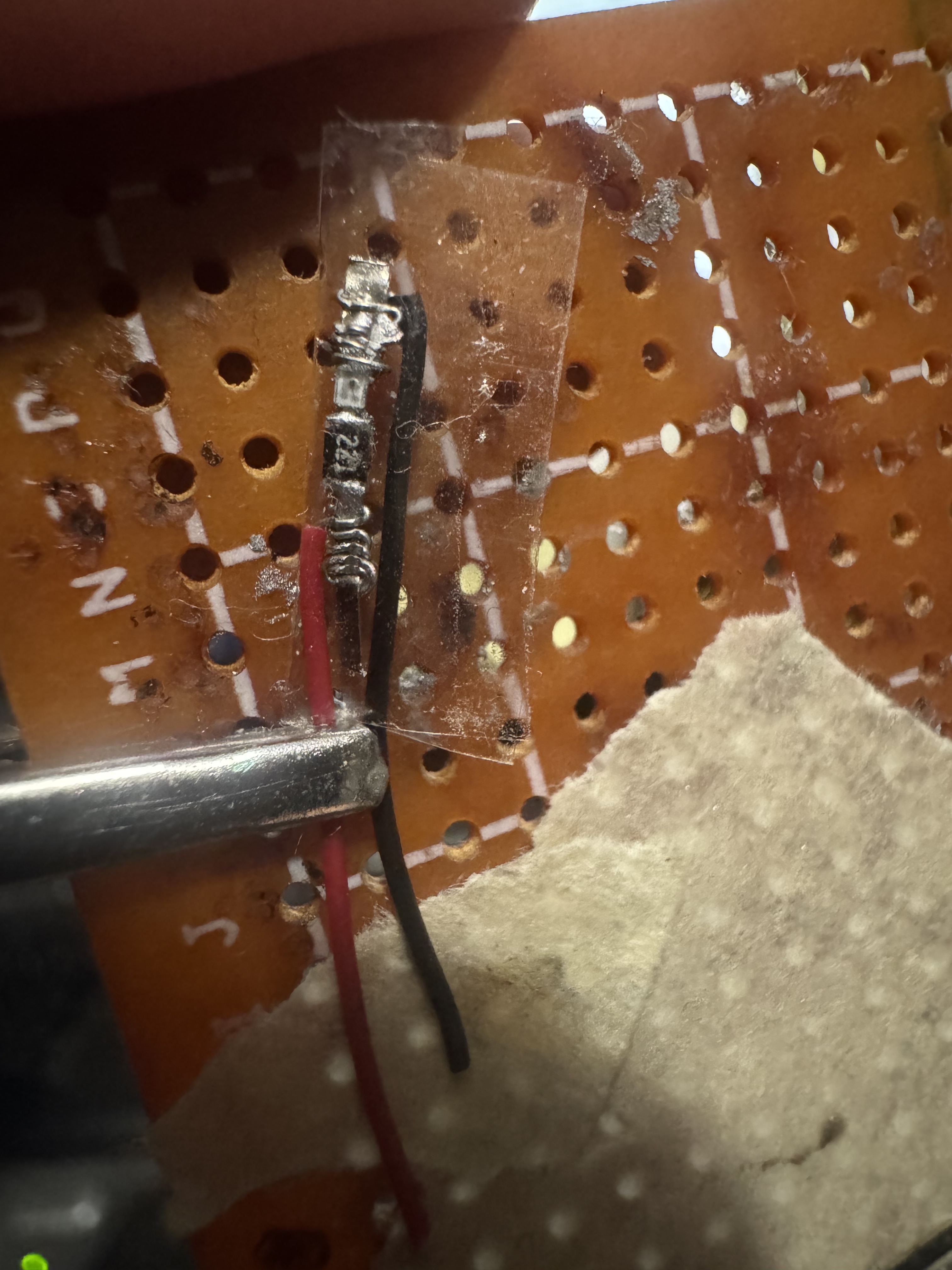

note: after wire wrapping the wire wrapping wire I noticed it was not that tight on there. I did not use a wire wrapping tool because I lost mine so I just used needle nose tweezers to manually wrap it around and around. Anyways to tighten it well I just crimped it with the tip of my wire strippers that has some kind of toothed pliers that crimps things well. After doing that the connection appears very solid. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #95, submitted 10/21/25 Well I finally got back to the electronics after about a month long detour real life interruption. All kinds of stuff slowed my progress on this session. But I got stuff done nonetheless. 0603 LED to 0805 resistor and some nickel strip leads coming off. Tested and working. This will be the indicator light for when the lowside mosfet comes on for one section of the custom BLDC motor controller. 0603 LEDs are extremely tiny for hand soldering and they don't take solder well either. I was originally going to go with blue LEDs but chatgpt said that would give off a unrealistic color through the silicone skin so orange would be better to give a more natural and less silicone skin piercing indicator light. Somehow I ran out of 470ohm resistors so I had to order more and I used my 200ohm ones instead for now. Which are a bit too bright. But chatgpt said I can diffuse the LED with a glob of silicone tinted black to darken and diffuse the light it gives off which sounds like a good idea to me. I am planning to use wire wrapping wire to come off of this assembly and tie into things. Somehow just attaching these two parts and testing it took me almost 3 hours. Between studying the schematic to refresh my memory on what is going on, visualizing placement options, overheating and destroying one LED, trying to locate the right color LEDs, shopping for replacement 470ohm resistors, researching and substituting in 200ohm resistors, discussing LED color options with chatgpt, figuring out how to solder a 0603 LED directly to a 0805 resistor part to part by hand, accidentally breaking a part off of its nickel strip lead and having to redo the connection, etc etc. All of it just crawls. Hard to stay patient with electronics sometimes and I do things in inefficient ways often. Learning what can and aught not to be done is tough from a patience perspective. But I insist on trial and error and experimentation which takes time. I just need to get into a daily habit to stick with it till completion. It's all complicated. Trying to figure out how to electronically isolate it all next. Thinking of using lamination plastic taped around it all so I can still see it all and visually troubleshoot. Also I'm considering how I can use solder wick braid as a heat pipe for each mosfet and run that over to the liquid cooling system. But it can't conduct. So thermally it can conduct but electrically it can't. Trying to figure out whether to create a barrier of micah or just thermal silicone for this and the routing needed. Also considering if I need mini coaxial shielded cable for the wiring of each or just regular wire wrapping wire when going from microcontroller to mosfets etc. Also trying to figure out if I need hall effect sensors or back emf reading or no feedback but my potentiometer and the implications of each option. Just so much to consider in all of this. And all of those considerations also slow things down even more as I have to make decisions on it all. It's quite overwhelming.

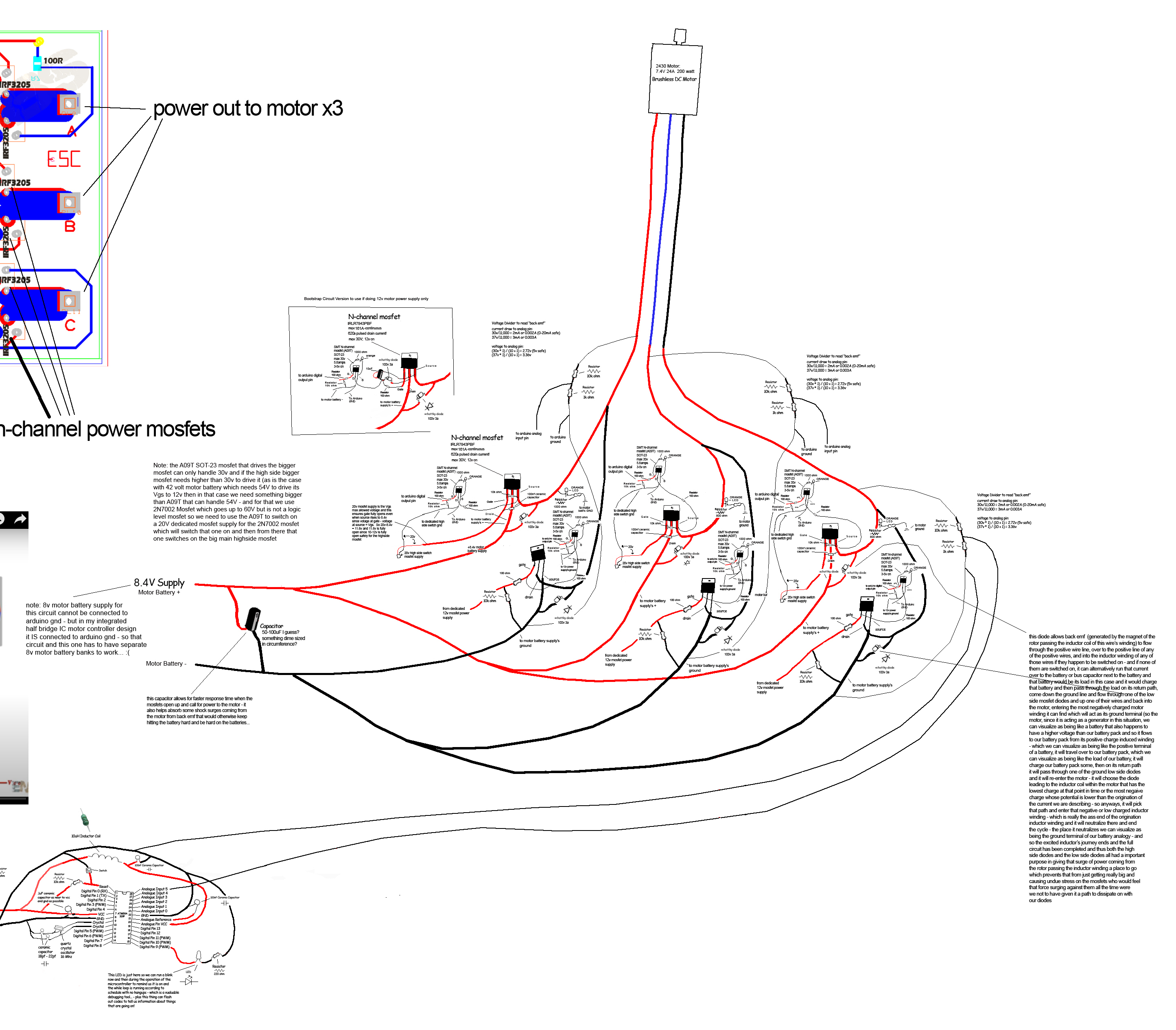

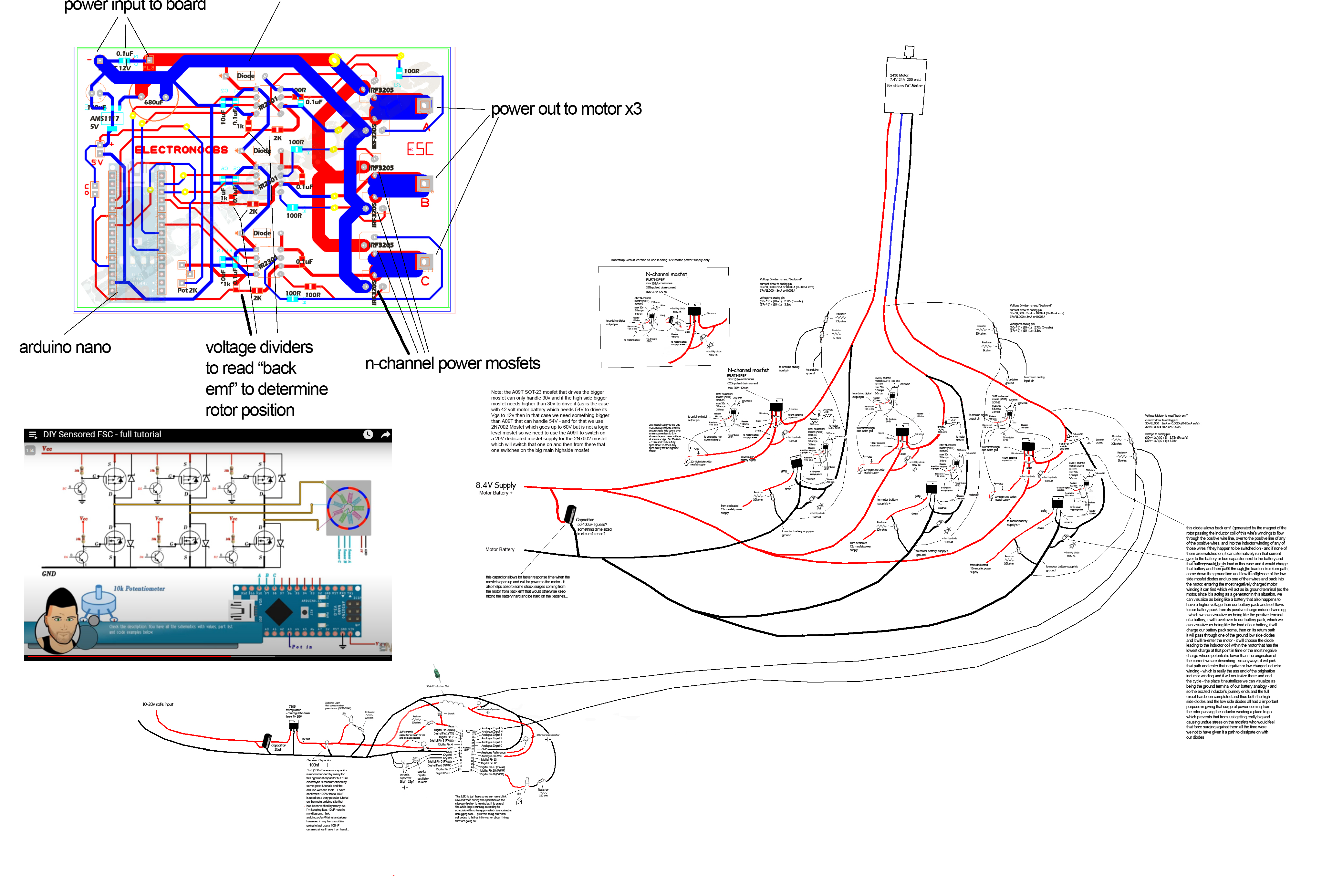

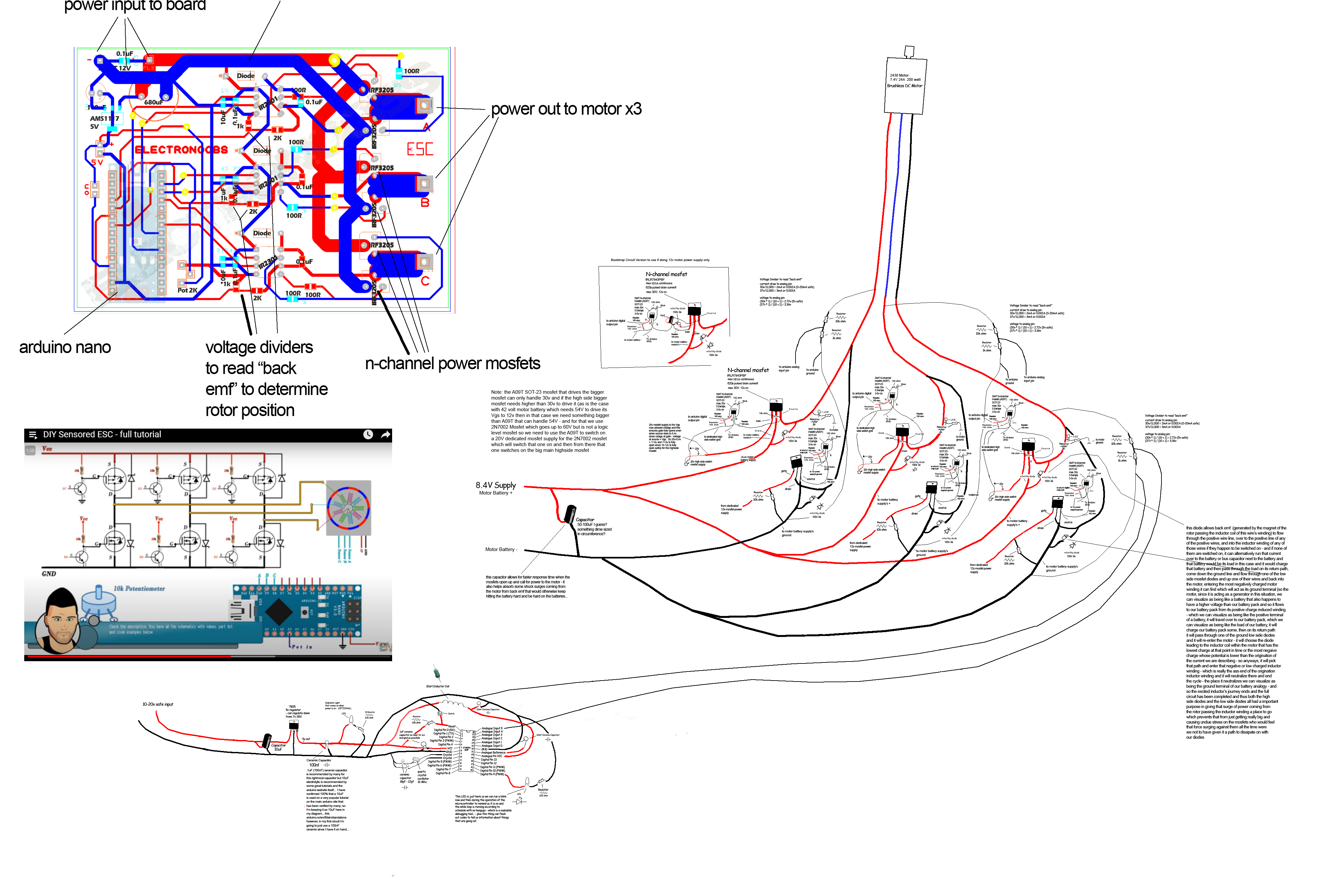

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #94, submitted 9/19/25 I started some testing on some subsections of the BLDC motor controller and ran into some problems and learned several things. I'm working with chatgpt to resolve each issue and have been updating my schematic to reflect alot of the changes I am making. One thing I learned is that for the high side switch, the voltage from gate to source has to be 10-12v higher than the drain voltage because the drain voltage becomes the same as the source voltage once the switch is on. The voltage from gate to source then either has to start out as motor input voltage + 12 while still fitting within the voltage from gate to source max allowed voltage as stated by the datasheet or it has to rise dynamically as the source voltage rises such that the voltage from gate to source is 12 more than the source voltage as the source voltage rises to become the drain voltage. Fortunately, I can have the former for this 2430 motor since I can use 6-8.4v to supply the motor and the voltage from gate to source max value is 20v. This means I can use voltage from gate to source of 20v and this, when mosfet is first switched on, does not fry mosfet but as the source rises to become 8.4v, 20v-8.4v is still 11.6v which is sufficiently high to enable the mosfet to still stay on without anything dynamic set up. If I want to go with a 12v motor supply on some of the bigger motors later on, I will need a bootstrap circuit to supply the highside mosfet with a dynamic voltage from gate to source that rises when source voltage rises. So I added that schematic diagram to this as well as an option. I also can use a mosfet driver for this but was hoping to cut that cost and added volume taken up by just using discrete components rather than a IC for this. Anyways, to break things down even more in testing, I decided to just test turning on and off a single highside mosfet using a pair of lab power supplies, one to provide 20v and one to provide 8.4v. To turn on I connected the gate and source to my 20v lab power supply and I connected my red alligator clip of my 8.4v lab power supply to the drain and then measured from source to the black lead of the 8.4v power supply and verified 8v on that test which worked - proving the mosfet was in fact on. I then removed the black alligator clip of the 20v lab power supply from source and shorted the source to the gate to drain the internal capacitor inside the mosfet and then tested from source to the black 8.4v clip and sure enough it was near 0v so was off. But it did gradually climb back up to 8.4v after the short from gate to source was removed due to capacitive coupling and leakage according to chatgpt. So I will need to add a 10k ohm resistor between gate and source pins to short it automatically and keep it fully drained and off fully when it's supposed to be off. So I plan to just gradually add components little by little and test after each thing is added to ensure it is working right still after each little change and this way gradually build out the circuit, proving each thing works as we go. This is because things have all these gotchas and "oh you didn't know this little detail?" that keeps coming up and proves it was more complicated than I thought. So I just have to prove every little thing as I go. To try to find out what is wrong after the whole thing is built would be WAY harder than to figure out what went wrong when a single component is added and it was working before said component was added. So that's how I will be able to overcome this challenge best I feel. Note: Reminder: I am building a custom BLDC motor controller because an off the shelf one would not have enough miniaturization to fit into the tight space constraints I have to work with. Also, building my own gives my software more precise control of every little advancement of the rotating magnetic field and along with that I'll have the ability to PWM the advancements to make them more smooth, less noisy, and have torque control as well this way which means the fingers can be rough and fast in movement as needed or slow and gentle and dainty or slow but powerful etc. I can also create acceleration profiles that match human finger joint acceleration in order to have the movements look very natural just like a human's movements which is very important to me. Just alot of fine precision is possible when its all my own circuit I feel. While off the shelf ones may have some of this functionality, the price often reflects that and is then prohibitive. But in any case nothing is off the shelf with this level of control AND the ability to so finely tune its form factor and volume envelope to fit my exact needs in space on a per motor basis.

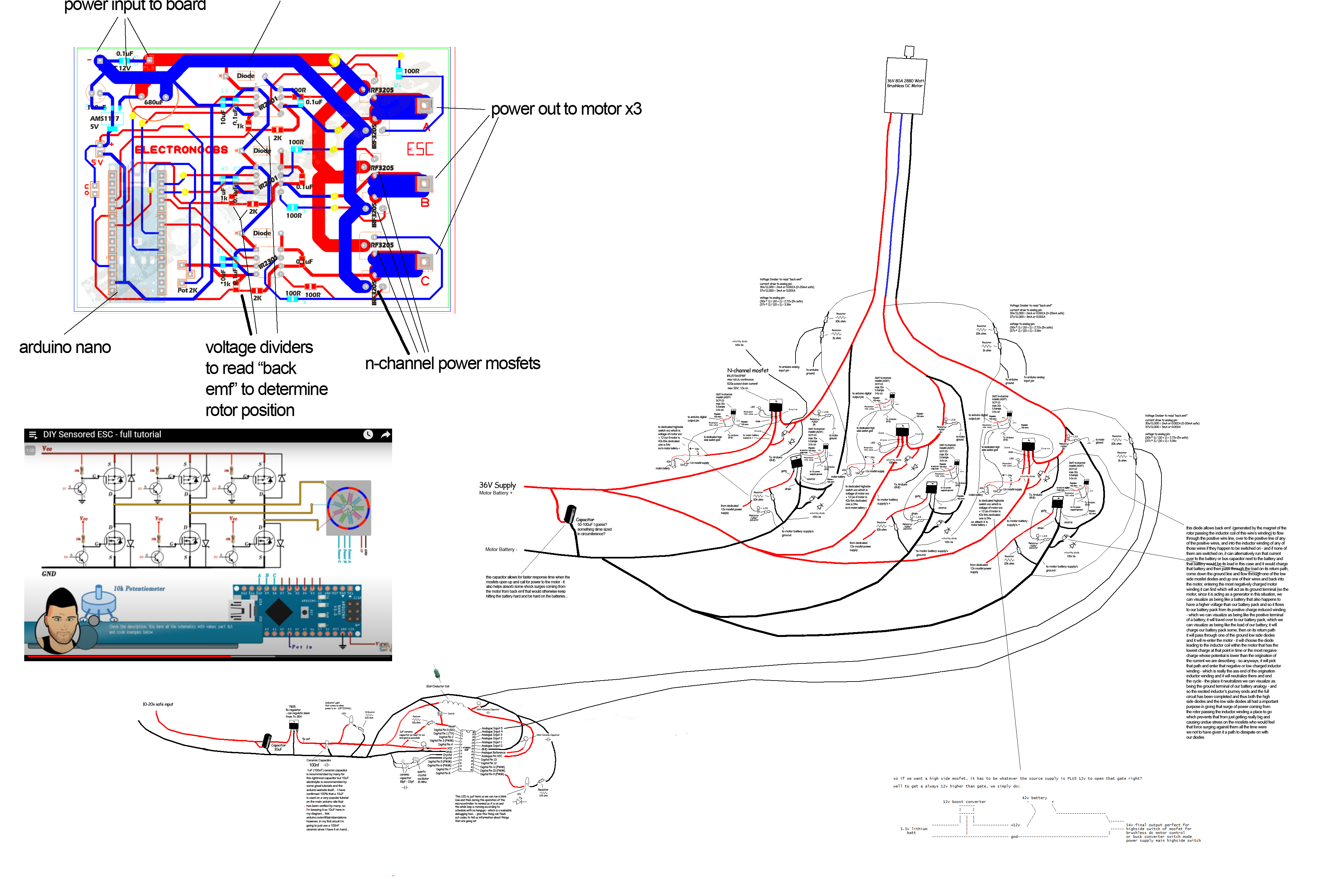

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #93, submitted 9/10/25 Back on the electronics again. Have been going over my BLDC motor schematic and making some little tweaks to it. Here's the updated schematic. It's a combination of lots of other schematics I've found online as well as some chatgpt help. With 1 being no clue and 10 being absolute expert tier in BLDC motor schematics I'm probably a 5 IMO. So take my design with a grain of salt. It will be very fun to see if it works. Note that I put a couple schematics of Electronoobs - a great youtuber on the left hand side as reference and study material. My schematic is the big one on the right. Electronoobs series of videos on BLDC motor controllers has been extremely helpful in me forming a rudimentary understanding of this stuff.

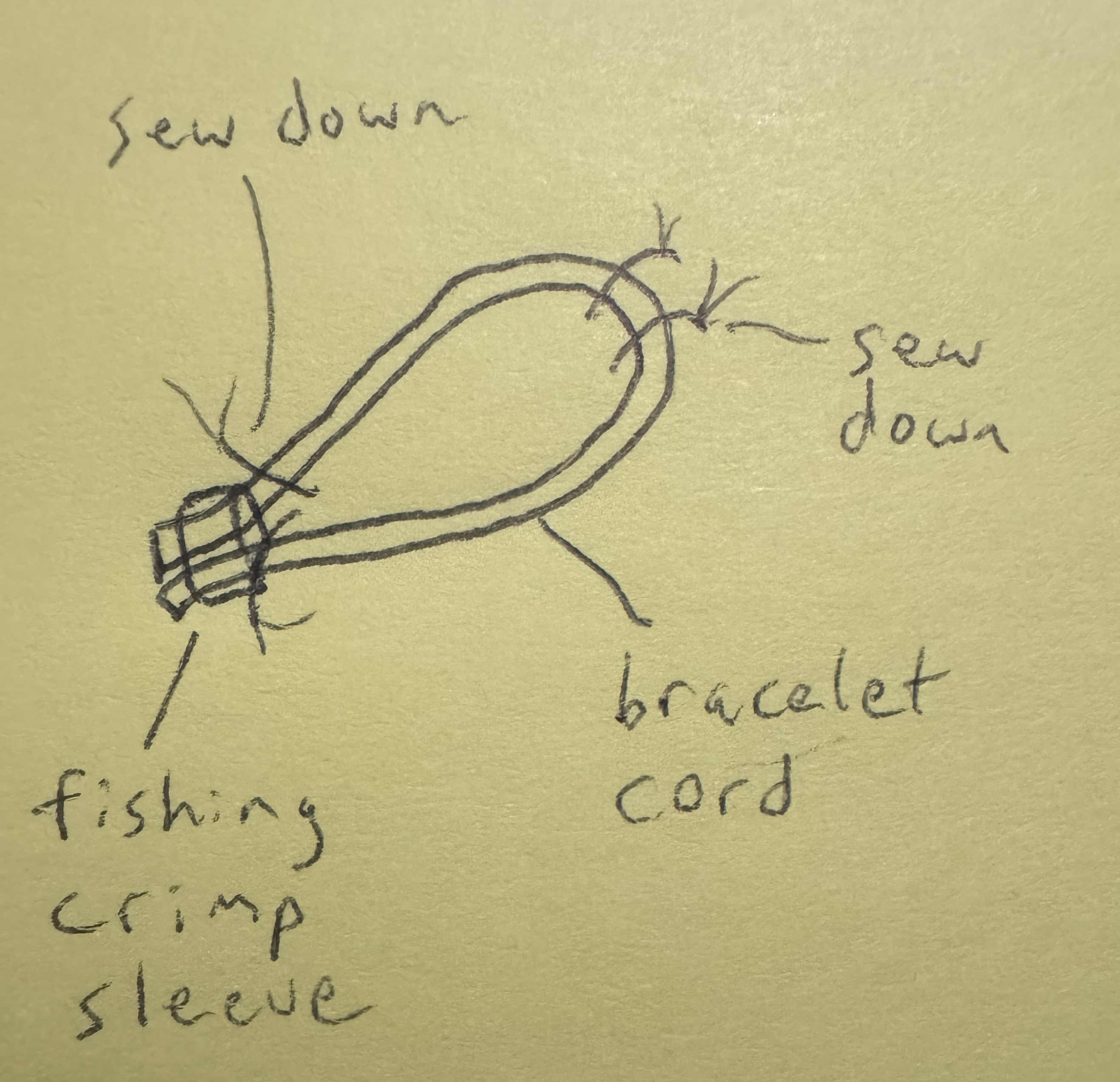

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #92, submitted 9/6/25 I installed two tensioners for the robot and they were seriously successful overall in testing. So much so that I am now confident enough in the entire pulley system to move onto the custom mini BLDC motor controller to get the motor to run motorized tests of finger movements next. Well after a couple very minor tweaks that is. So the first tensioner I installed on the extension part of the index finger joint we are working on. I used the bracelet cord folded in half and fishing crimp sleeved then sewn into the bone fabric. It seems just about perfect except for one thing: I want to keep it under mild constant tension but the bone fabric creeps/moves slowly when put under constant tension like this because it is taped into place on the bone after all. The tape is allowing the movement. This means it does not stay put and my anchor points move over time so I can't set a tension and rely on it staying at that tension long term. To resolve this I need a mechanical connection at the tension point anchoring location.

To mechanically connect my anchor point, I have decided to use tiny self tapping screws. I have avoided screwing into the bones till now but I'm making an exception here. The screws won't be going that deep and the finger bones are unlikely to break anyways IMO. So I feel comfortable with this. Here's the screws I ordered for this from Amazon:

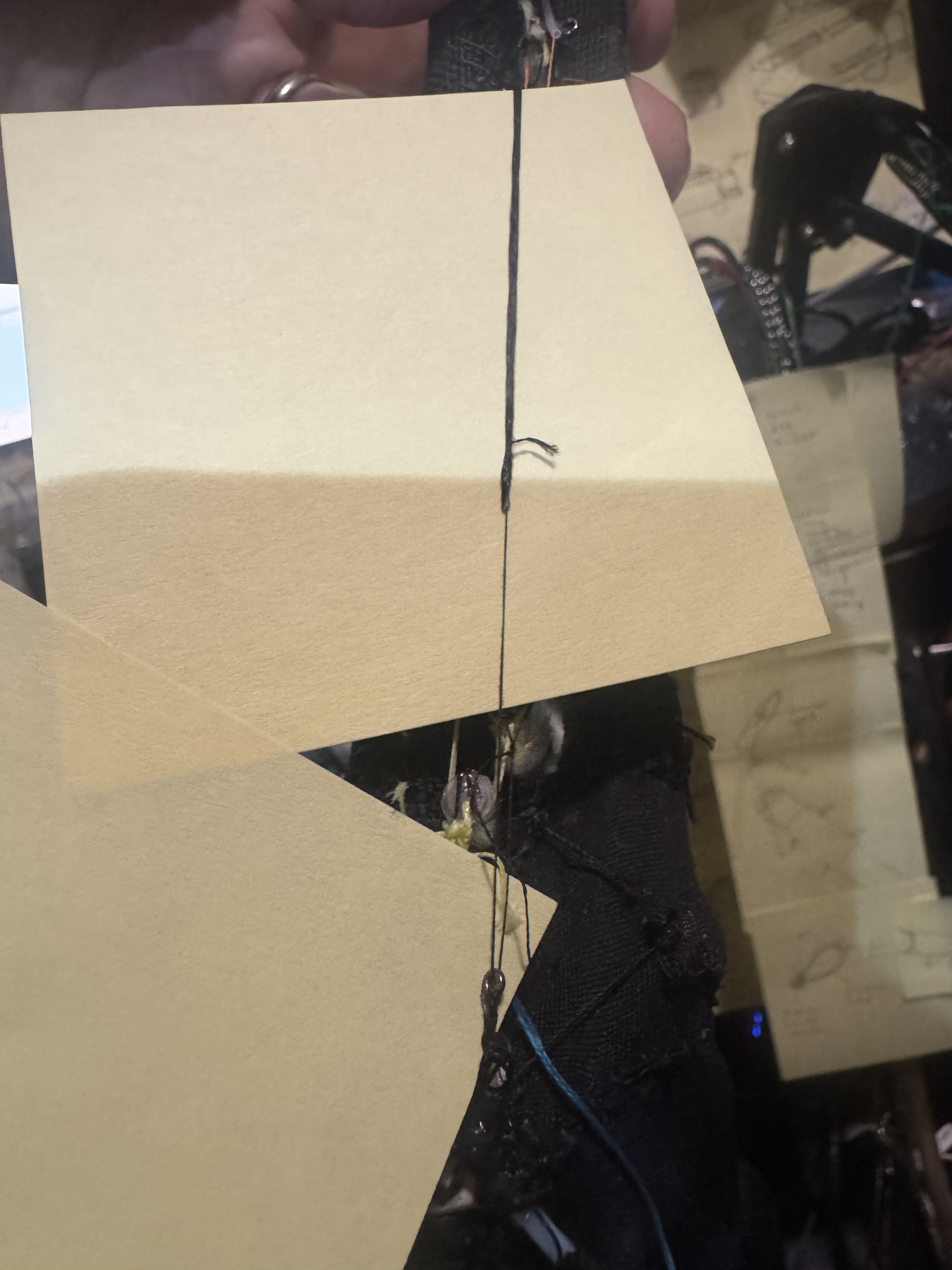

Next, I created a tensioner for the middlemost archimedes pulley. That pulley was creating significant drag and slowing down the finger extension during testing due to rope friction. So adding a tensioner line to pull it back down toward the fingers during extension was my solution for this. It worked amazingly well. To make this, first I tied off a fishing hook eye to the bottom of the radius bone just above where my TPFE guide tubing entrance is. Then I glued a 7cm piece of bracelet cord to a piece of 6lb test .08mm braided pe fishing line with 401 glue. I secured the top of the bracelet cord to the top of the archimedes pulley system and then threaded the other end through the fishing hook eye and back up and to the bottom of the archimedes pulley where I tied it off. So it ties off at top, comes down to bottom, goes through the fishing eye then comes back up and connects to my pulley. It creates just enough downward pull to delete the rope drag slowing down that pulley from coming down and this enables the system to unwind and extend back to its starting point after each time I contracts/pulls upward to cause finger contraction. This means the finger extension now happens swiftly with no hangups and the whole archimedes pulley system is now under constant tension at all times which keeps things neat and prevents tangling issues pre-emptively. This rig was a massive success and took up hardly ANY space at all. I put the post it notes behind the archimedes pulley tensioner so you can see it. It's hard to see otherwise without a contrasting backdrop. It works amazingly well.

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #91, submitted 9/6/25 Okay so the bracelet cord self untied quickly so I'm going back to my previous approach of tying off both ends of the bracelet cord with a fishing crimp sleeve. While trying to cut in half fishing crimp sleeves with my mini miter saw I noticed it was a difficult process and not ideal. So I came up with a easier method which was way faster, cleaner, less setup and takedown, no deburring needed, etc! The method is to lay the fishing crimp sleeve on a flat surface and line up a exacto knife blade perpendicular to it across its top and then apply moderate downward pressure to score the metal and then slide the knife carefully back and forth creating a perfect scoring line that grows deeper with each pass. After several passes the fishing crimp sleeve halves separate cleanly! This method uses a similar principle to a copper pipe cutter used in plumbing.

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #90, submitted 8/27/25 Ok I figured out a bit easier way: tie a knot at each end of the strip of bracelet cord and then tie my nylon thread off onto the bracelet cord inside that bracelet cord knot. The bracelet cord knot on each end acts as an endstop. Seems to work great so far and cuts down on materials this way over the previous way I proposed.

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #89, submitted 8/20/25 I figured out a robust way to make the extension cord for finger extension using the bracelet cord and a fishing crimp sleeve. The idea is to crimp the two ends of a folded in half strip of bracelet cord and this way both ends can be sewn down into the fabric without any gluing which could potentially fail or be a weak point. I am planning to use this in place of the tension spring style finger extension setup.

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #88, submitted 8/2/25 So in recent testing a fresh issue I ran into was the TPFE tubing would start gradually pulling through its tightly wrapped tape sleeve to my surprise. Its low friction surface gradually pulls free of the tape over time. To resolve this, I decided to thread through the tip of the tubing to create a mechanical bond for the tip and once threaded through I just 401 glued down the ends of each thread onto the sleeve that was originally supposed to hold it in place to begin with. This seems to work great so far in the little bit of testing I've done since.

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #87, submitted 8/1/25 The tension spring mounted to the motor setup upon further testing seems like a somewhat bad method. The issue I'm having is too much play in the tubing running between that spring and the finger joint. When tension is applied to that spring by way of the tubing, the tubing recoils and moves quite alot and allows alot of slack out to the joint so that the spring has very little involvement in the joint and doesn't really get used much period. So the full range of motion of the joint is just absorbed by tubing slack. When I tried to pretension the tubing so that the joint movement translates to the spring, the total tension placed on the joint by this became too high. Fortunately, I came up with a much more elegant and simple solution for all of this. Basically, my plan now is to just use the bracelet cord tied point to point across the joint directly on the joint and that will be my spring for extension that counters the motor. This eliminates the need for metal springs at all which cuts costs, it also eliminates the PTFE tubing run, saving some space, and should be easier to install and easier to give precise amount of elasticity/resistance to taste. If I want more springback on the joint I can just add more bracelet cord in parallel to the first. This way I can add more resistance pretty easily.

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #86, submitted 7/21/25 I finally finished making the tensioner mechanism for the winch in place pulley and I taped it off up the string descending from the ceiling and taped the far end of it onto the ceiling. I noticed I have to keep it as straight as possible since when curling with too much turning the elastic bracelet cord grips the sides of the PTFE tubing which could interfere with the amount of tension it brings to my winch in place pulley. So this will mean on the robot itself it will have to go from the shoulder all the way down the torso in a straight line and then down the leg to about the knee as well. It's 44" long in total. I ended up bumping up the elastic bracelet cord to 30" long to reduce the amount of tension it puts on the winch in place pulley more. The longer it is the less tension it brings and the shorter it is the more tension it brings. If it really can't fit into the leg I can cut the elastic bracelet cord in half and place braided PE fishing line in between the two halves and have that make a 180 degree turn around a pulley and thereby have the same length of elastic bracelet cord but separated into two halves mounted parallel to eachother that create a in series matching tension but taking up half the overall length. This way I could keep it out of the leg area if needed. However I think it might fit into the leg area fine perhaps. Not sure (once we get all the other motors and their tension strings that amount of 2.2mm OD PTFE tubing will start to add up.

Note: I'm also considering taking the elastic bracelet cord out of the tubing and lubing it then putting it back in since lube on the grippy elastic bracelet cord would take away it gripping the sides of the PTFE tubing some I think. Silicone lube is best for this according to chat gpt. Note: to secure the far end of the elastic bracelet cord I used 401 glue to glue on PE fishing line onto its end the same way as we discussed before and then took the far end of this PE fishing line and came out the end of the PTFE tube with it and taped it off onto the outside of the tube. We'll see how that holds up it might need to be glued down if it gradually is pulled through the tape over time which would be no good. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #85, submitted 7/19/25 Minor update: I have now carefully mounted the PTFE tubing that leads to the elastic string tensioner for the winch in place pulley. I mounted it snugly to the side of the PTFE tubing coming off the same winch in place pulley that leads to the Archimedes pulley system. I routed both of these using my CAD for reference in such a way that their routing will not interfere with the next motors that will be installed later. I mounted this PTFE tubing that leads to the elastic string tensioner using ONLY 401 glue which is something I've never tried before now. Usually I first wrap the tubing in adhesive transfer tape and spandex cloth wrap and coat the cloth in 401 glue but skipping that made it able to be more snugly mounted to the other tube by way of only glue. We'll see how that holds up without the other reinforcement the cloth provides etc. Seems to look so far so good though. They are in turn glued to paper soaked with 401 glue and to a little piece of stainless steel wire bent at a 90 and that wire in turn glued to the winch in place pulley mount baseplate which is itself made of paper and 401 glue. So basically everything is becoming 401 glue construction! I have some concerns about how this will hold up in the event of a fall or w/e but perhaps we can create some sort of protective cage around any delicate outcroppings like this in the future. For now I am just going for ease of construction and speed of construction to get things back on track and rolling again.

Note: The PTFE tubing that leads to the elastic string tensioner for the winch in place pulley is 0.66mm ID 1.16mm OD PTFE teflon tubing. The string coming off the winch in place pulley feeding into this tubing that will act as tensioner string tension carrier string is 6lb test 0.08mm PE braided fishing line. I was able to thread this fishing line into this TPFE tubing by hand with no issues at all very easily. The next task will be to mount the end of this string to the 2 feet of elastic string for jewelry making and thread that into 1.8mm ID 2.2mm OD PTFE tubing and tie it off at the end of that tubing and then mount that tubing to the gray string hanging from my ceiling for now. That will conclude the tensioner mechanism for the winch in place pulley and this will usher in the next round of manual hand testing to see how much tension that is giving us. I also will be moving the tension spring mounted on the motor to align it better and shorten it more since it only moves like 4mm and so can be way shorter than it is now. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #84, submitted 6/13/25 Sometimes to get the braided PE fishing line threaded through the fine PTFE tubing can be tricky, so I came up with a neat device to assist in this. I will be making a threading tool based on a needle threader tool I've been using. It's basically a wire folded in half that you shove through a needle eye and then stick your string into its end and then pull it back through the needle eye. In my use case, I'm creating a custom one of these threading tools that will feed through my entire length of tubing till its folded end comes out the other side and I can thread my string through that end and then draw it back, bringing the string through the tubing with it.

I just ordered some 40ga copper and stainless steel wire to use to make this device in question. I'll see which metal is best. Gonna try the copper first I think. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #83, submitted 5/22/25 Ok so I currently have an order for 0.2x1x1000mm tension springs stuck in customs for weeks and placed another order just today for the same in hopes it goes through faster. But at $9 for a single spring that is 3ft long, I am feeling RIPPED OFF on price. It is bullcrap. All relating to the tariff nonsense. So I decided today to pivot and just roll with the elastic band in place of tension spring. It's a jewelry making elastic band I bought some time ago in a roll. WAY cheaper at $0.03 for 3ft instead of $9 for 3ft. That's 99.7% off! Talk about a discount! The issue I had before when I looked into this option was the tie-off point. I would need a way to tie PE fishing line to the end of the elastic band without the tie point being bulky. Well I figured out a way to do it without any bulk at all! See I want this to fit into my 1.8mm ID PTFE tubing to keep size down. My solution was to just glue the fishing line lengthwise directly to the elastic band. No knot at all. No turns at all. Just literally lay it on top and glue it down flush. I figured about 6mm length of joint would be solid. And I did this on both sides with my PE fishing line. I used 0.08mm 6lb test braided PE fishing line for this. So now I have two fishing line segments coming off the end of it for double the strength of this connection. But I only wanted one piece of fishing line to go the distance to attach to the motor end so I twisted the pair of fishing line segments together and glued the twisted pair with 401 glue then cut one of the two away leaving just one of the pair to go the distance to the winch in place pulley that this is all supposed to tension for me. I will use this string and elastic band method for now as I wait on springs and stick with this method for at least this first motor actuator setup for now. If the elastic bands don't last, we'll upgrade to the metal springs later on during maintenance or w/e. Note: the total length of the elastic band I am using for this is 2ft and it stretches to 3ft snugly without too much force. I'm just going by feel and instinct for this measurement. If I were to go 1ft with 1ft of stretch, the stretch is more intense and the pull is harder. But I don't think I need much pull for just tensioning the winch in place pulley and I also think the more tension you place the more wear and tear on the elastic band which will shorten its lifespan. So playing it conservatively with the 2ft length selection for now. Note: to apply the 401 glue I used an exacto knife handle with a sewing needle in place of the xacto knife blade and the tip of the sewing needle acts as my precision glue applicator. Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #82, submitted 5/10/25 Good news: I had mentioned before I was planning to use 2mm OD tension spring for the winch in place pulley tension solution but once I got the 3mm ID 4mm OD PTFE tubing to go over the spring, I saw that the 4mm was just WAY too big once you multiply that out to 300 motors. 300 of 4mm OD tubing starts to take up a massive area at that point and I struggled with that. I MUST be miserly on space taken up by parts to get all the crap I need to fit in there to fit in there! Anyways, I fortunately discovered that you can buy tension spring down to 1mm in OD! I was unaware of this before now! You can find it if you search "0.2x1.5x1000mm tension spring" where 0.2mm is wire thickness, 1.5mm is OD, 1000mm is length. So I ordered 1mm OD tension spring and 1.5mm OD tension spring to test and see what seems best. If the 1mm OD spring seems reliable to me, I'll go with it. Anyways, since the spring is now smaller, I can use also a smaller PTFE tubing to house the spring so I ordered uxcell PTFE Tubing 1.8mm ID x 2.2mm OD off amazon. 2.2mm OD tubing compared to 4mm tubing is SHOCKINGLY smaller when you look at them. So it will be WAY more space efficient now. Here's my updated tension spring concept drawing:

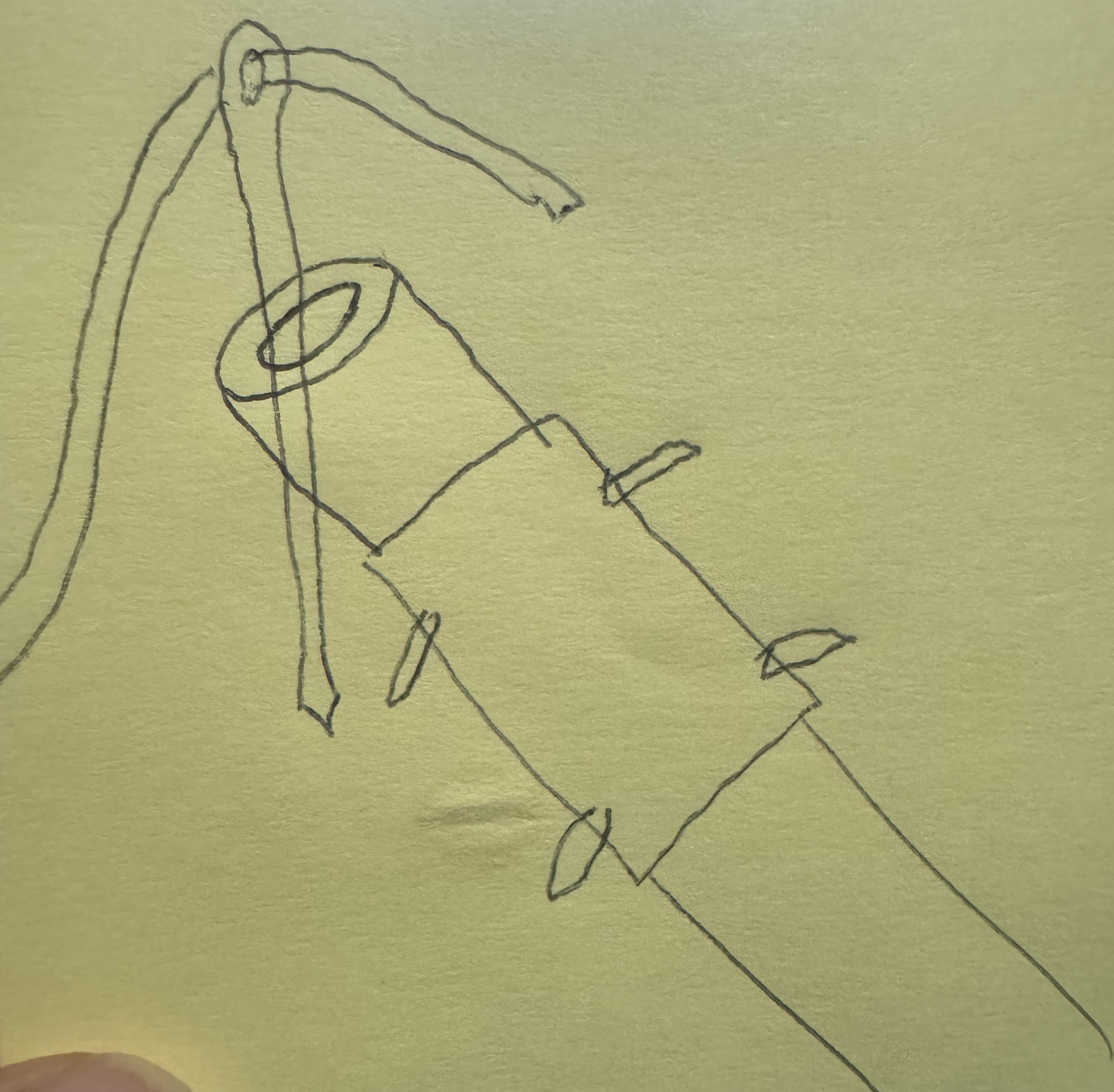

Drop a Comment: Comments: ---------------------------------------------------------------------------- Blog Post #81, submitted 4/29/25 After further consideration, I'm scrapping using the elastic cord for a bracelet idea (as a tension spring for the winch in place pulley). The point of that was to use as little space as possible but I just don't trust it. I am not sure what material it is made of and my experience with rubber bands has always been dry rot issues. I am going with 2mm OD tension spring instead. It has to stretch 12.5" and so I'm using a 12.7" strip of it to start. That feels like a snug stretch but does comfortably reach the 12.5" of stretch needed. This brings its stretched total length to 25.2". I bought 3mm ID 4mm OD TPFE tubing to be its guidance tube for this. That arrives tomorrow and then I can begin assembly. This 4mm OD guidance tube is a bit bulky and long for the arm IMO so I will relocate it to the torso since if I use this method for other motors these 4mm OD tubes will add up in space taken up fast. The arm can't house them - it's just too much space taken at that point for these. But the torso can house them in the back or sides I think. For now, since the torso is not yet attached, I'm going to place this tube ON the string suspended from my ceiling and treat that string as though it were the torso for now. Here is the tension spring in question from the paragraphs above. I want this spring inside the tubing though which is not shown in the drawing of it.

Drop a Comment: Comments: Older Posts |

|

|||

|

||||

| *REGISTERED NAMES AND TRADEMARKS ARE THE PROPERTY OF THEIR RESPECTIVE OWNERS. |

|

Page Hits: 23877. |